The Releated Products of Granite Diamond Wire Saw

Granite Diamond Wire Saw

Table of Contents

Granite Diamond Wire Saw: Precision Cutting for Modern Applications

In the realm of construction and stonework, precision and efficiency are paramount. One tool that has revolutionized the industry by providing unparalleled accuracy and speed is the granite diamond wire saw. This advanced cutting technology has become indispensable for projects requiring the cutting of large blocks of granite and other hard stones. Here’s a closer look at how this powerful machine works, its benefits, and applications across various sectors.

Granite Diamond Wire Saw Technology

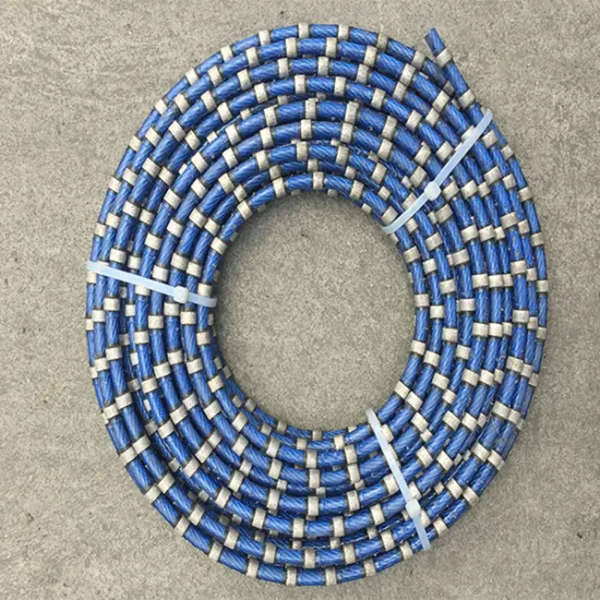

The core of a granite diamond wire saw lies in its diamond-impregnated wire, which rotates at high speeds to cut through materials like granite, marble, and concrete. Unlike traditional saws that use blades, the wire saw’s flexibility allows it to maneuver around obstacles and make precise cuts in tight spaces. The continuous loop of wire, embedded with industrial diamonds, ensures smooth, clean cuts every time.

Benefits of Using a Granite Diamond Wire Saw

Adopting a granite diamond wire saw comes with numerous advantages over conventional cutting methods. Firstly, it significantly reduces noise levels compared to other cutting tools, making it ideal for urban areas where noise pollution is a concern. Additionally, it generates minimal dust, improving air quality at the work site. Its ability to cut at any angle also enhances versatility, enabling complex designs and shapes to be achieved with ease.

Applications of Granite Diamond Wire Saws

From quarrying operations to architectural projects, the granite diamond wire saw finds application across diverse industries. In quarries, these saws are used to extract large slabs of stone with minimal waste. For construction purposes, they excel in creating openings in existing structures without damaging surrounding materials. Furthermore, their precision makes them perfect for creating intricate patterns on countertops and floors during remodeling tasks.

Maintenance of Granite Diamond Wire Saws

To ensure optimal performance and longevity of your granite diamond wire saw, regular maintenance is essential. This includes inspecting the wire regularly for wear or damage, cleaning the saw after each use to prevent buildup of debris, and lubricating moving parts as recommended by the manufacturer. Proper storage in a dry environment when not in use can also help extend the life of the tool.

Advancements in Granite Diamond Wire Saw Technology

As technology continues to evolve, so too does the design and functionality of granite diamond wire saws. Newer models are becoming more efficient, incorporating features such as variable speed controls and improved tracking systems. These innovations not only enhance productivity but also contribute to safer working conditions. Research into new diamond compositions and wire materials promises even greater durability and cutting capabilities in the future.

Training and Safety Considerations for Using a Granite Diamond Wire Saw

Given the power and complexity of these machines, proper training is crucial for operators. Training programs typically cover safe operating procedures, emergency shutdown protocols, and routine maintenance checks. Emphasizing safety from the start helps prevent accidents and ensures that all users understand how to handle the equipment correctly. Always follow manufacturer guidelines and local regulations regarding personal protective equipment (PPE) and workplace safety standards.

By understanding the capabilities and potential of the granite diamond wire saw, professionals in the stone and construction industries can leverage this tool to achieve outstanding results while maintaining high standards of safety and sustainability. As advancements continue, we can expect these remarkable machines to play an increasingly important role in shaping our built environment.

Request for Quotation

报错: 未找到这个表单