The Releated Products of Granite Diamond Saw Blade

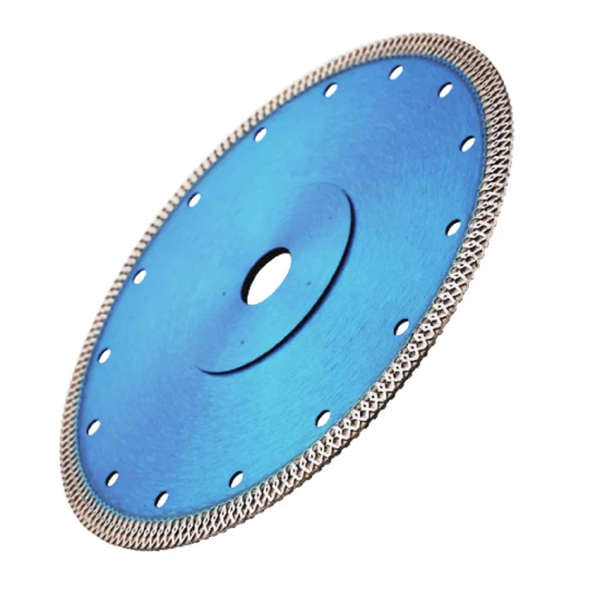

Granite Diamond Saw Blade

Table of Contents

Understanding the Durability of Granite Diamond Saw Blades

When it comes to cutting through tough materials like granite, having the right tool can make all the difference. Granite diamond saw blades are specifically designed for this purpose, offering unmatched durability and precision. These blades are crafted with a combination of metal bonding and diamond segments, which allows them to handle the most demanding cutting tasks without compromising performance.

The Composition of Granite Diamond Saw Blades

The core of a granite diamond saw blade is typically made from steel, providing a sturdy base. Around this core, a layer of industrial diamonds is embedded into a metal bond. This bond serves as the glue that holds the diamonds in place while cutting. Depending on the type of material being cut, manufacturers may choose different types of bonds—such as bronze, electroplated, or resin—to ensure optimal performance.

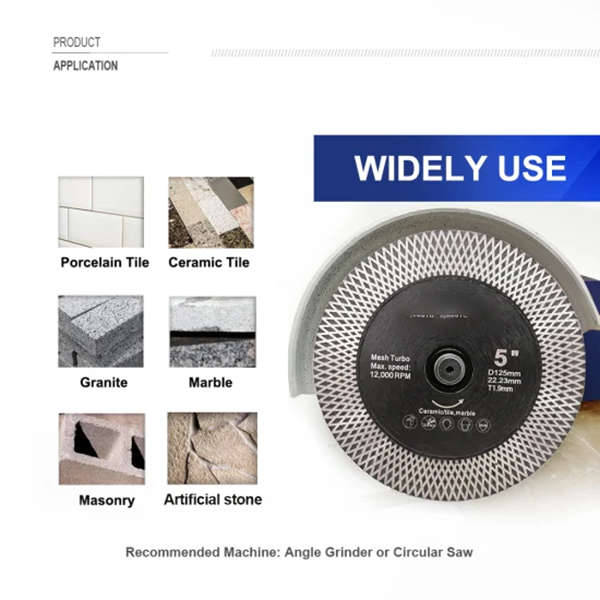

Applications of Granite Diamond Saw Blades

Granite diamond saw blades find their use in various industries, including construction, stone fabrication, and renovation projects. They are ideal for cutting granite countertops, paving stones, and other hard stone materials. The ability of these blades to cut through such dense materials efficiently makes them indispensable tools for professionals who require precision and reliability in their work.

Choosing the Right Size and Type of Granite Diamond Saw Blade

Selecting the appropriate size and type of blade is crucial for achieving the best results when working with granite. Factors such as the thickness of the material, the hardness of the stone, and the specific requirements of the project should all be considered. For instance, a wet saw blade might be preferred over a dry one when continuous operation is required, as it helps reduce dust and overheating.

Maintenance and Care of Granite Diamond Saw Blades

To ensure longevity and maintain optimal performance, proper care and maintenance of granite diamond saw blades are essential. After each use, cleaning the blade thoroughly to remove any debris is recommended. Storing the blade in a dry place and protecting it from corrosion will also extend its life. Regular inspection for wear and tear can help identify when it’s time to replace the blade, preventing potential accidents and ensuring consistent quality in cuts.

Advantages of Using Granite Diamond Saw Blades

One of the primary advantages of using granite diamond saw blades is their ability to deliver clean, precise cuts even through the hardest materials. Their durability means they can withstand prolonged use without significant degradation, making them cost-effective in the long run. Additionally, advancements in technology have led to improvements in blade design, further enhancing their efficiency and reducing the effort required during the cutting process.

Future Innovations in Granite Diamond Saw Blades

As technology continues to evolve, so too does the design and functionality of granite diamond saw blades. Newer models are focusing on increasing the lifespan of the blade, improving cutting speed, and reducing environmental impact. Innovations in materials science are contributing to the development of more efficient bonding agents and diamond configurations, promising even better performance in future generations of these essential tools.

Request for Quotation

报错: 未找到这个表单