The Releated Products of Granite Cutting Tools

Granite Cutting Tools

Table of Contents

Granite Cutting Tools: Precision Meets Durability

In the realm of construction and stonework, precision and durability are paramount. Granite, known for its exceptional hardness and aesthetic appeal, poses unique challenges when it comes to cutting and shaping. This has led to the development of specialized granite cutting tools designed to handle this demanding material with ease and accuracy. From diamond blades to waterjet cutters, let’s explore the essential tools every granite worker needs.

Diamond Blades for Granite Cutting

Diamond blades stand out as one of the most effective granite cutting tools available today. These circular saws feature industrial diamonds embedded in their outer edge, which allows them to slice through granite with minimal effort. When choosing a diamond blade, consider factors such as segment height, bond hardness, and diamond concentration. For instance, softer bonds work better on harder materials like granite because they allow the diamonds to wear away more quickly, exposing fresh cutting edges.

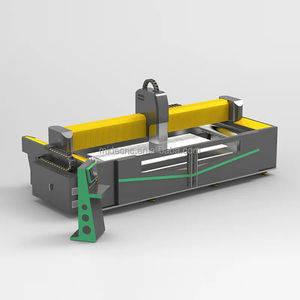

Waterjet Cutters: A Versatile Option Among Granite Cutting Tools

Waterjet cutting technology represents another innovative approach to tackling tough jobs like granite cutting. By using a high-pressure stream of water mixed with abrasive particles (typically garnet), waterjets can cut through virtually any material, including granite, without generating heat or causing thermal damage. This makes them ideal for intricate designs and detailed work where precision is key.

Router Bits for Polishing and Edging

While often overlooked, router bits play a crucial role in finishing processes associated with granite cutting tools. After the initial cut, these bits help smooth out rough edges and add decorative profiles to countertops and other surfaces. Made from tungsten carbide, they provide the necessary hardness and sharpness required to work efficiently on granite without dulling too quickly.

Manual Tools for Small-Scale Granite Cutting

For smaller projects or quick fixes, manual granite cutting tools offer a cost-effective alternative to heavy machinery. Tools like diamond-tipped scoring wheels and hand-held nippers are perfect for making precise cuts and adjustments in pre-cut slabs. Though they require more physical effort compared to powered options, they still deliver accurate results when used correctly.

Safety Gear Essential for Using Granite Cutting Tools

Safety should never be compromised when working with granite cutting tools. Dust masks, safety goggles, and ear protection are non-negotiable items that protect against the harmful effects of silica dust and noise pollution generated during cutting operations. Additionally, proper handling techniques and regular maintenance of tools can prevent accidents and prolong the lifespan of your equipment.

Choosing the Right Tool for Your Project

Selecting the appropriate granite cutting tool depends largely on the specific requirements of your project. Consider the size and complexity of the job, your budget constraints, and personal skill level when deciding between different types of tools. Consulting with experienced professionals or conducting thorough research beforehand can save time and ensure a successful outcome.

By understanding the capabilities and limitations of various granite cutting tools, you can tackle even the most challenging projects with confidence. Whether you’re a seasoned professional or just starting out, investing in quality tools will make all the difference in achieving professional-grade results.

Request for Quotation

报错: 未找到这个表单