The Releated Products of Granite Cutting Table

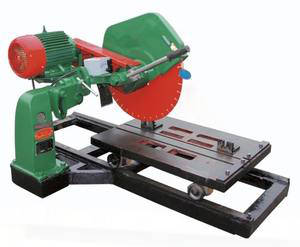

Granite Cutting Table

Granite Cutting Table: Precision, Durability, and Efficiency

In the world of stone fabrication, precision and efficiency are paramount. This is where the granite cutting table comes into play, offering unparalleled accuracy and durability. Whether you’re a seasoned professional or just starting out in the industry, understanding the benefits and features of a granite cutting table can significantly enhance your operations.

Choosing the Right Granite Cutting Table

Selecting the right granite cutting table for your workshop involves considering several factors. First, assess the size and scale of your projects. A larger table will accommodate bigger slabs, increasing productivity. Next, examine the material thickness capacity—some tables are better suited for thicker materials. Lastly, consider the type of cutting technology used, as this directly impacts precision and speed.

Features of a High-Quality Granite Cutting Table

A high-quality granite cutting table is built to last, featuring robust construction materials such as stainless steel or aluminum. These materials resist corrosion and wear, ensuring long-term reliability. Additionally, look for tables equipped with advanced waterjet or CNC routing systems, which provide superior cutting accuracy and reduce waste.

Maintenance Tips for Your Granite Cutting Table

To keep your granite cutting table operating at peak performance, regular maintenance is essential. This includes cleaning the cutting area thoroughly after each use to prevent residue buildup. Lubricating moving parts periodically helps maintain smooth operation. Also, inspecting and replacing worn components like blades or seals when necessary ensures consistent quality output.

Safety Considerations When Using a Granite Cutting Table

Safety should always be a top priority when working with power tools, especially something as powerful as a granite cutting table. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and ear protection. Ensure all guards are in place and functioning correctly. Familiarize yourself with emergency stop procedures and have a first aid kit readily available.

Enhancing Productivity with Your Granite Cutting Table

To maximize productivity, consider integrating automation technologies with your granite cutting table. Automated cutting processes can increase throughput while maintaining high levels of accuracy. Training staff on efficient workflow practices and utilizing software for job scheduling also contributes to enhanced productivity without compromising quality.

Customizing Your Granite Cutting Table Setup

Depending on specific needs, customizing your granite cutting table setup can further improve functionality. This might involve adding specialized attachments for intricate cuts or integrating dust collection systems to maintain a cleaner workspace. Tailoring your table to fit unique project requirements ensures optimal performance across various applications.

By investing in a well-designed granite cutting table, stone fabricators can achieve greater precision, efficiency, and overall satisfaction in their work. From choosing the right model to maintaining it properly, every step plays a crucial role in maximizing the benefits of this indispensable piece of equipment.

Request for Quotation

报错: 未找到这个表单