The Releated Products of Granite Cutting Blade For Grinder

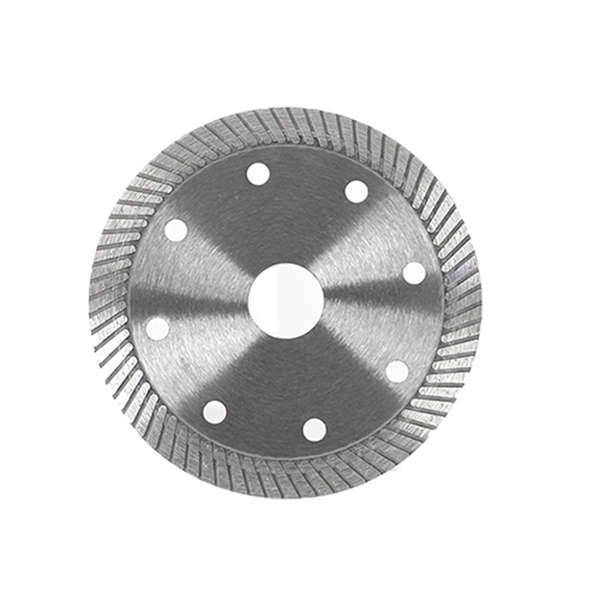

Granite Cutting Blade For Grinder

Table of Contents

Choosing the Right Granite Cutting Blade for Your Grinder

When it comes to cutting granite, having the right tools can make all the difference. A high-quality granite cutting blade for grinder ensures precision, durability, and efficiency. Whether you’re a professional contractor or a DIY enthusiast, understanding the features and benefits of different blades can help you choose the best one for your project.

Understanding the Basics of a Granite Cutting Blade for Grinder

Before diving into specifics, it’s essential to understand what makes a granite cutting blade for grinder unique. These specialized blades are designed to handle the extreme hardness and abrasiveness of granite. They typically feature diamond segments that are bonded to a steel core. The diamonds embedded in the segments do the actual cutting, while the steel core provides stability and support during operation.

Factors to Consider When Selecting a Granite Cutting Blade for Grinder

When choosing a granite cutting blade for grinder, several factors come into play:

1. Diamond Segments: The quality and composition of the diamond segments directly affect the blade’s performance. Higher-quality diamonds will last longer and cut more efficiently.

2. Bond Type: The bond refers to how the diamond is attached to the segment. Harder bonds are better suited for softer materials like granite because they allow the diamonds to wear away more slowly.

3. Blade Thickness: Thicker blades offer more stability but may be slower. Thinner blades are faster but might be less durable.

Benefits of Using a High-Quality Granite Cutting Blade for Grinder

Investing in a top-notch granite cutting blade for grinder offers numerous advantages:

– Enhanced Cutting Speed: Premium blades cut through granite more quickly, reducing overall project time.

– Increased Durability: Stronger blades mean fewer replacements and lower costs over time.

– Smooth Cuts: High-quality blades produce cleaner edges with less chipping or cracking, ensuring a professional finish.

Maintenance Tips for Your Granite Cutting Blade for Grinder

Proper care extends the life of your granite cutting blade for grinder and maintains its cutting efficiency:

– Regular Inspection: Check the blade regularly for signs of wear or damage.

– Cooling Techniques: Keep the blade cool by using water during cutting to prevent overheating.

– Storage: Store the blade in a dry place away from corrosive substances.

Applications of a Granite Cutting Blade for Grinder

The versatility of a granite cutting blade for grinder allows for use in various applications:

– Construction Projects: Ideal for cutting countertops, floors, and walls in commercial and residential settings.

– Lapidary Work: Used by jewelers and artists for precise cuts on gemstones and other hard materials.

– DIY Projects: Perfect for homeowners looking to install their own granite surfaces.

Conclusion: The Importance of Choosing the Best Granite Cutting Blade for Grinder

Selecting the most suitable granite cutting blade for grinder depends on your specific needs and the nature of your work. By considering factors such as diamond quality, bond type, and blade thickness, you can ensure that your tool performs optimally every time. Regular maintenance and proper usage will further enhance the longevity and effectiveness of your blade, making it an invaluable asset in any workshop or construction site.

Request for Quotation

报错: 未找到这个表单