The Releated Products of Granite Cutting Blade For Circular Saw

Granite Cutting Blade For Circular Saw

Table of Contents

Choosing the Right Granite Cutting Blade for Your Circular Saw

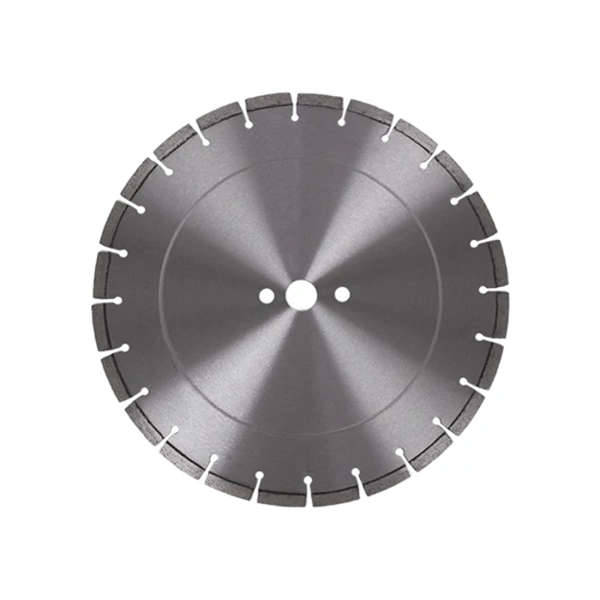

When it comes to cutting granite, selecting the right tool can make all the difference. A granite cutting blade for circular saw is essential for achieving clean, precise cuts without damaging the material or the tool itself. Whether you’re a professional contractor or a DIY enthusiast, understanding the key features and benefits of these specialized blades will help you choose the best one for your project.

Importance of Using a Granite Cutting Blade for Circular Saw

Granite is a dense, hard material that requires a specialized blade to cut effectively. A standard saw blade simply isn’t up to the task and can result in jagged edges, chipping, and even damage to the saw. A granite cutting blade for circular saw, on the other hand, is designed specifically for this type of work. It has a robust construction that allows it to handle the rigors of cutting through tough materials like granite while maintaining its sharpness and durability.

Types of Granite Cutting Blades for Circular Saws

There are several types of granite cutting blades for circular saws available on the market, each with its own set of advantages and applications. Diamond blades are among the most popular choices due to their ability to cut through extremely hard materials. They come in wet and dry versions, with wet diamond blades requiring a continuous stream of water to keep the blade cool and reduce dust. Dry diamond blades, on the other hand, do not require water and are ideal for indoor use where water might be a problem.

Turbo-grit blades are another option, featuring a segmented rim with small segments that provide a smoother cut and faster material removal compared to continuous rim blades. These are particularly useful when precision is paramount, such as in countertop fabrication.

Factors to Consider When Selecting a Granite Cutting Blade for Circular Saw

When choosing a granite cutting blade for circular saw, several factors should be taken into account to ensure optimal performance and longevity. The size of the blade is crucial; it must match the specifications of your circular saw. Additionally, consider the thickness of the blade, which affects both the speed of the cut and the precision of the finish. Thinner blades offer a more precise cut but may wear out faster, while thicker blades are more durable but slower.

The material composition of the blade is also important. For instance, diamond blades come in different grades—bond hardness—that affect how they perform on specific materials. Softer bonds are better suited for harder materials like granite because they allow the diamonds to wear away at a rate that keeps them exposed for cutting.

Maintaining Your Granite Cutting Blade for Circular Saw

Proper maintenance of your granite cutting blade for circular saw is essential for extending its lifespan and ensuring consistent performance. After each use, inspect the blade for any signs of wear or damage. Clean it thoroughly to remove any debris or residue that could affect its cutting efficiency. Store the blade in a dry, protected area to prevent rust and corrosion.

Regularly checking the blade’s mounting and ensuring it is properly tightened can prevent accidents and improve cutting accuracy. Over time, if you notice that the blade is no longer cutting as smoothly or efficiently as it once did, it may be time for replacement.

Safety Precautions When Using a Granite Cutting Blade for Circular Saw

Safety should always be a top priority when working with power tools, especially when cutting materials as hard as granite. Always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and a dust mask. Make sure the blade is properly secured to the saw and that the saw is equipped with a guard to protect against kickback.

When using a wet granite cutting blade for circular saw, be cautious of electrical hazards and ensure that the saw is plugged into a ground-fault circuit interrupter (GFCI) outlet. Follow the manufacturer’s instructions for operating the saw and the blade to avoid accidents and achieve the best results.

Conclusion

Investing in a high-quality granite cutting blade for circular saw is a smart choice for anyone looking to tackle tough cutting jobs with ease and precision. By considering the factors discussed above and following proper maintenance and safety guidelines, you can ensure that your blade remains a reliable tool for many projects to come.

Request for Quotation

报错: 未找到这个表单