The Releated Products of Granite Cutter Blade

Granite Cutter Blade

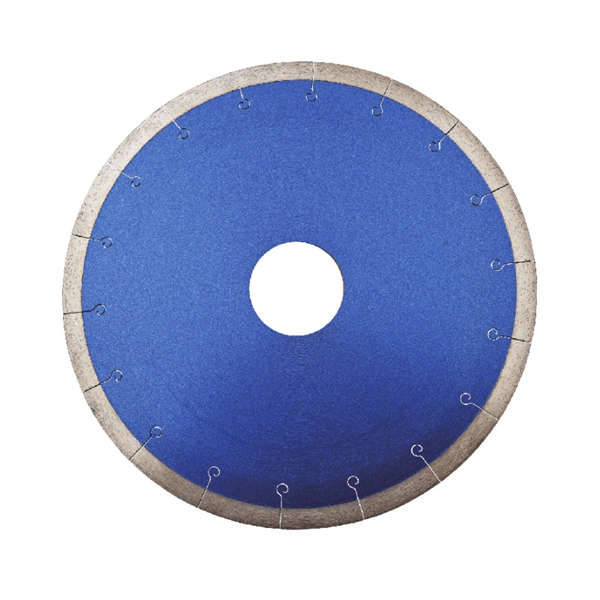

Granite Cutter Blade: Precision, Power, and Performance

In the world of construction and stonework, precision and durability are paramount. This is where the granite cutter blade shines, offering unparalleled performance in cutting through one of nature’s hardest materials—granite. Understanding the nuances of these blades can help professionals select the right tool for their projects, ensuring efficiency and safety. Let’s delve into the specifics of granite cutter blades, exploring their construction, types, applications, and maintenance.

Choosing the Right Granite Cutter Blade

Selecting the right granite cutter blade is crucial for achieving clean cuts and prolonging the life of your equipment. Blades designed specifically for granite feature diamond segments that are optimized for hardness and grit size to efficiently cut through this tough material. Consider the blade’s diameter, thickness, and bond type when making your selection, as these factors significantly impact its performance.

When choosing a blade, pay close attention to its intended application. For instance, wet cutting blades are ideal for reducing dust during operation, making them a safer option in confined spaces. Dry cutting blades, on the other hand, offer more flexibility but may require additional safety measures due to increased dust production.

The Construction of a Durable Granite Cutter Blade

A high-quality granite cutter blade is built to withstand extreme conditions. The core of the blade is typically made from steel, providing stability and support. Attached to this core are diamond segments, which do the actual cutting. These segments consist of synthetic diamonds embedded in a metal matrix, or bond, which holds them together and to the blade itself.

Manufacturers use different bonds depending on the hardness of the material being cut. Soft bonds are better suited for harder stones like granite because they allow the blade to wear down at a rate that keeps the diamonds exposed for optimal cutting. Harder bonds are used for softer materials, ensuring the diamonds don’t wear out too quickly.

Applications of Granite Cutter Blades

Granite cutter blades find extensive use across various industries, including construction, countertop fabrication, and monument creation. In construction, these blades are essential for cutting granite slabs used in flooring, walls, and decorative elements. Countertop fabricators rely on them to produce custom pieces with smooth edges and precise dimensions.

Monument makers also benefit greatly from using specialized granite cutter blades. They enable the creation of intricate designs and smooth finishes on headstones and memorials, honoring the memory of loved ones with lasting beauty and craftsmanship.

Maintaining Your Granite Cutter Blade

Proper maintenance is key to extending the lifespan of your granite cutter blade and maintaining its cutting efficiency. Regularly inspect the blade for any signs of wear or damage, such as cracks or missing segments. Replace worn-out blades promptly to avoid compromising the quality of your work or risking injury.

Cleaning your blade after each use helps prevent the buildup of debris that can interfere with its performance. Use a wire brush to remove any residual stone particles, then rinse thoroughly with water. Store your blade in a dry place away from direct sunlight to prevent rusting and ensure it remains in top condition for future use.

Advantages of Using a Granite Cutter Blade

The advantages of using a granite cutter blade are numerous. Not only do they provide a fast and efficient way to cut through granite, but they also offer superior accuracy compared to traditional tools. This results in cleaner cuts with fewer jagged edges, reducing the need for additional finishing work.

Additionally, modern granite cutter blades are designed with safety features that protect both the user and the equipment. Features like dust extraction ports and water cooling systems help maintain a safe working environment by minimizing airborne particles and preventing overheating during prolonged use.

By investing in a high-quality granite cutter blade, professionals can achieve exceptional results while enhancing productivity and ensuring long-term reliability of their tools. Whether you’re tackling a large-scale construction project or creating bespoke stonework pieces, the right blade makes all the difference.

Request for Quotation

报错: 未找到这个表单