The Releated Products of Granite Blades

Granite Blades

The Unmatched Durability of Granite Blades

When it comes to cutting through tough materials like stone, concrete, or even granite itself, few tools can match the efficiency and durability of granite blades. These specialized tools, often referred to as diamond blades due to their construction, are designed to withstand extreme conditions and provide precise cuts. In this article, we will explore the unique features, applications, and maintenance requirements of granite blades, highlighting why they are indispensable in various industries.

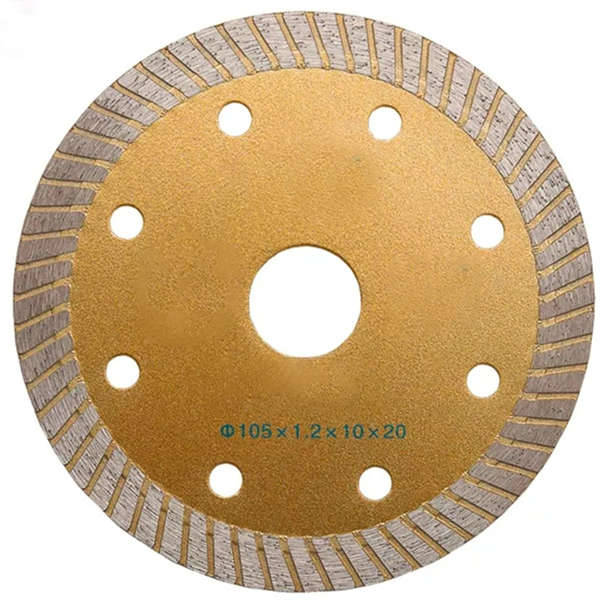

Key Components of Granite Blades

Understanding the composition of granite blades is crucial for appreciating their performance. Typically, these blades consist of a steel core with a segment or rim embedded with industrial diamonds. The steel core provides stability and strength, while the diamond segments enable effective cutting. The quality of the diamond concentration, bond hardness, and segment height all play significant roles in determining the blade’s lifespan and cutting efficiency.

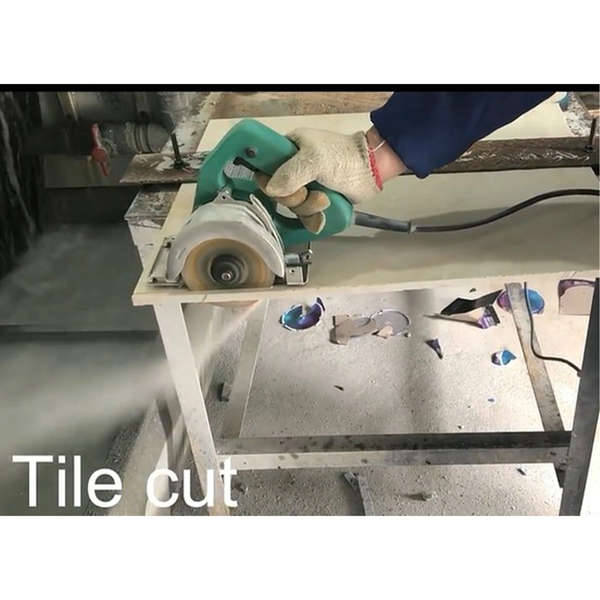

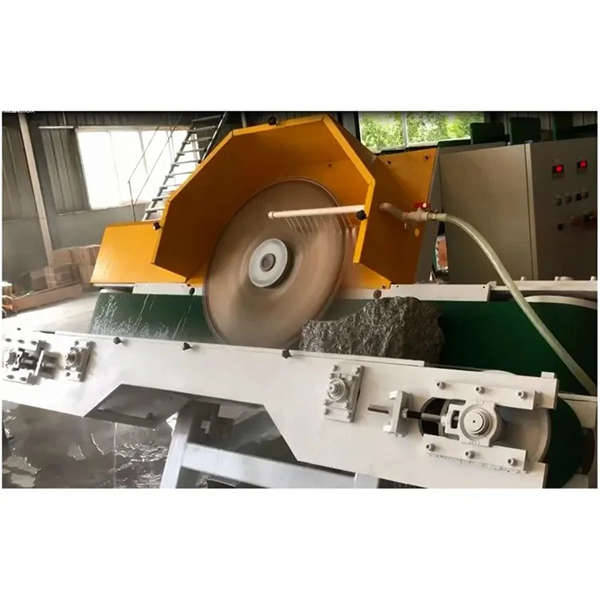

Applications of Granite Blades in Construction

Granite blades find extensive use in construction projects, where they are employed for cutting a variety of materials. From shaping granite countertops to slicing through concrete floors, these blades offer unparalleled precision and speed. Their ability to cut wet or dry makes them versatile tools for both indoor and outdoor applications. Moreover, advancements in technology have led to the development of blades suitable for specific materials, further enhancing their utility.

Maintaining the Performance of Granite Blades

To ensure optimal performance and longevity, proper maintenance of granite blades is essential. Regular inspection for wear and tear, along with cleaning the blade after each use, can significantly extend its life. Avoiding overloading the blade and using it within its intended capacity also prevents premature damage. Additionally, storing granite blades in a cool, dry place away from corrosive substances helps maintain their integrity.

Choosing the Right Granite Blade for Your Project

Selecting the appropriate granite blade depends on several factors, including the material being cut, the thickness of the workpiece, and the desired finish. For instance, softer materials might require blades with softer bonds to prevent glazing, whereas harder materials call for stronger bonds to protect the diamonds from chipping. Consulting with experts or manufacturers can provide valuable insights into choosing the best blade for specific applications.

Environmental Impact and Sustainability of Using Granite Blades

As industries increasingly focus on sustainability, the environmental impact of manufacturing and using granite blades becomes a pertinent topic. While the production process involves high energy consumption, efforts are underway to develop more eco-friendly alternatives. Recycling old blades and promoting the use of high-quality, durable products that last longer contribute to reducing waste and environmental footprint.

Advancements in Granite Blade Technology

Innovation continues to drive improvements in granite blade technology, aiming to enhance performance and reduce operational costs. Newer designs incorporate features such as improved diamond retention, enhanced cooling systems, and reduced noise levels. These advancements not only make the blades more efficient but also safer and easier to handle, benefiting both professional users and DIY enthusiasts alike.

By keeping abreast of these developments and adhering to best practices in selection and maintenance, professionals can maximize the benefits offered by granite blades, ensuring they remain a cornerstone tool in modern construction and fabrication processes.

Request for Quotation

报错: 未找到这个表单