The Releated Products of Granite Blade For Grinder

Granite Blade For Grinder

Table of Contents

Granite Blade for Grinder: Cutting Precision and Durability

When it comes to cutting through granite, a material known for its hardness and durability, having the right tool is essential. A granite blade for grinder is specifically designed to handle this challenging task with ease and efficiency. This article will explore the key features, benefits, and considerations when choosing a granite blade for grinder, ensuring you make the best selection for your project needs.

Understanding the Importance of a Granite Blade for Grinder

Before diving into the specifics, it’s crucial to understand why a specialized granite blade for grinder is necessary. Unlike standard blades, these tools are engineered with advanced materials and designs that can withstand the extreme hardness of granite. They provide clean, precise cuts without chipping or damaging the surface, which is particularly important when working on high-quality stone projects.

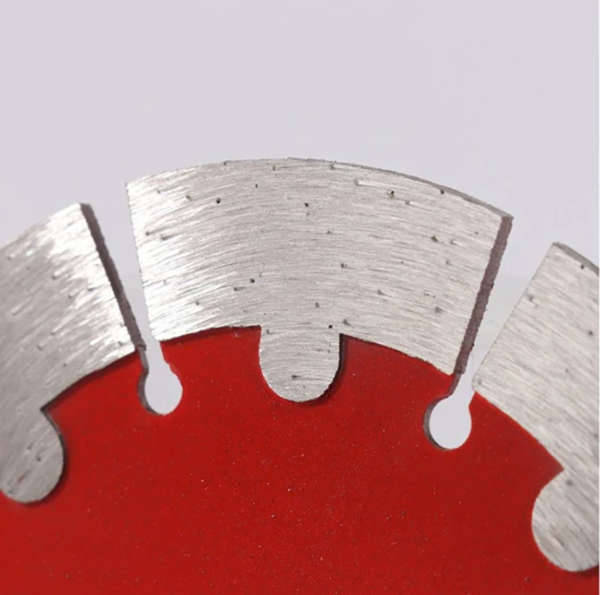

Selecting the Right Diamond Segments for Your Granite Blade for Grinder

The diamond segments are the cutting edges of a granite blade for grinder. These segments are made from synthetic diamonds embedded in a metal matrix. The type of bond (how the diamonds are held in place) and the concentration (number of diamonds per volume) determine the blade’s performance. For granite, a medium-hard bond is typically recommended as it provides a good balance between cutting speed and blade life.

Maintaining Your Granite Blade for Grinder

To ensure optimal performance and longevity, proper maintenance of your granite blade for grinder is essential. After each use, clean the blade thoroughly to remove any debris or buildup. Regular inspections can help identify signs of wear or damage early, preventing accidents and prolonging the blade’s service life. Following manufacturer guidelines for storage and handling will also contribute significantly to maintaining the blade’s condition.

Advantages of Using a Granite Blade for Grinder

Using a granite blade for grinder offers several advantages over general-purpose blades. Firstly, they are far more efficient at cutting through granite, reducing the time required for each cut. Additionally, because they are designed specifically for this task, they produce cleaner edges with minimal chipping or cracking. This precision is invaluable in applications where aesthetics are critical, such as countertop fabrication.

Tips for Choosing the Best Granite Blade for Grinder

When selecting a granite blade for grinder, consider factors like the size of the blade, the type of diamond segment used, and the overall quality of construction. Larger blades may be necessary for bigger projects, while smaller ones offer better control for detailed work. Always opt for reputable brands known for their durability and performance. Reading reviews from other users can provide valuable insights into real-world performance and reliability.

Applications of a Granite Blade for Grinder

From kitchen countertops to bathroom vanities, the applications of a granite blade for grinder are numerous. Professional stonemasons, contractors, and DIY enthusiasts alike benefit from the precision and efficiency these specialized tools offer. Whether you’re working on a large commercial project or a small home renovation, having the right blade makes all the difference in achieving professional results.

By investing in a high-quality granite blade for grinder, you’re setting yourself up for success in any project involving this beautiful yet challenging material. With proper care and regular maintenance, your blade will serve you well, delivering consistent performance and helping you achieve stunning results every time.

Request for Quotation

报错: 未找到这个表单