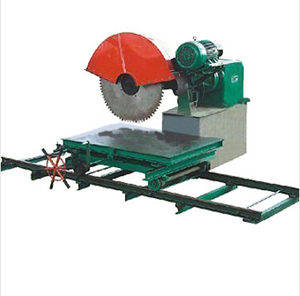

The Releated Products of Flat Stone Cutting Disc

Flat Stone Cutting Disc

Understanding the Versatility of Flat Stone Cutting Discs

In the realm of construction and stonework, precision and durability are paramount. Among the essential tools for cutting through stone, concrete, and other hard materials, the flat stone cutting disc stands out. This powerful accessory for angle grinders and cut-off machines offers unparalleled performance when it comes to slicing through tough surfaces. Whether you’re a professional contractor or a DIY enthusiast tackling home renovation projects, understanding the capabilities and benefits of these discs can greatly enhance your work efficiency.

Enhancing Efficiency with Flat Stone Cutting Discs

When it’s time to cut stone, whether for landscaping projects or building facades, choosing the right tool is crucial. Flat stone cutting discs are designed specifically for this purpose. Their robust design allows them to handle both wet and dry cutting applications, making them incredibly versatile. The segmented rim of these discs ensures clean cuts with minimal chipping, even on the most delicate stones. By investing in high-quality flat stone cutting discs, professionals can significantly boost their productivity while maintaining high standards of craftsmanship.

Key Features of Effective Flat Stone Cutting Discs

To get the best results from a flat stone cutting disc, several key features should be considered:

– Segment Design: Segmented discs have notches around the edge which help in dissipating heat and reducing vibration during operation.

– Diamond Grit Quality: The quality and concentration of diamond grit directly impact the cutting speed and lifespan of the disc.

– Core Design: A well-designed core supports efficient material removal while also providing stability and balance to the disc.

Understanding these components helps in selecting a disc that matches specific job requirements, ensuring optimal performance and longevity.

Applications of Flat Stone Cutting Discs

From granite countertops to marble flooring, flat stone cutting discs find extensive use across various industries. In construction, they are indispensable for creating precise cuts in paving stones, bricks, and concrete blocks. Similarly, in the world of art and sculpture, artisans rely on these discs to shape and refine their creations. The ability of flat stone cutting discs to deliver accurate, smooth cuts makes them a favorite among professionals looking to achieve the perfect finish every time.

Maintenance Tips for Flat Stone Cutting Discs

Proper care and maintenance are vital to extending the life of your flat stone cutting discs. After each use, clean the disc thoroughly to remove any debris that might interfere with its performance. Store discs in a cool, dry place away from direct sunlight and extreme temperatures. Regular inspection for signs of wear such as cracks or chips is recommended; replace any damaged discs immediately to avoid accidents. Following these simple guidelines ensures that your cutting discs remain in top condition, ready for the next project.

Choosing the Right Flat Stone Cutting Disc for Your Project

Selecting the appropriate flat stone cutting disc depends largely on the material being cut and the desired outcome. For softer stones like limestone, a disc with a softer bond may be sufficient. Harder materials like granite require a harder bond to prevent premature wear. Consider factors like the size and thickness of the disc, the type of machine it will be used with, and the expected frequency of use. Consulting with experts or referring to manufacturer recommendations can help in making an informed decision tailored to your specific needs.

By focusing on these aspects, users can ensure that their flat stone cutting discs perform optimally, contributing to successful project completions and satisfied clients.

Request for Quotation

报错: 未找到这个表单