The Releated Products of Drive Wheel For Diamond Wire Saw

Drive Wheel For Diamond Wire Saw

Drive Wheel for Diamond Wire Saw: Enhancing Precision and Efficiency

In the realm of construction and material cutting, precision and efficiency are paramount. One tool that has revolutionized the way we cut through hard materials like stone, concrete, and metal is the diamond wire saw. A key component of this versatile cutting tool is the drive wheel for diamond wire saws. This article explores the importance of the drive wheel, its types, maintenance, and how it contributes to the overall performance of diamond wire saw systems.

Importance of the Drive Wheel for Diamond Wire Saw

The drive wheel serves as the heart of any diamond wire saw system. It’s responsible for transmitting power from the motor to the wire, ensuring smooth and controlled cutting. Without a properly functioning drive wheel, the saw would not be able to achieve the required tension and speed necessary for efficient cutting operations. Understanding the role of the drive wheel can help operators maximize their machine’s potential and maintain optimal operational standards.

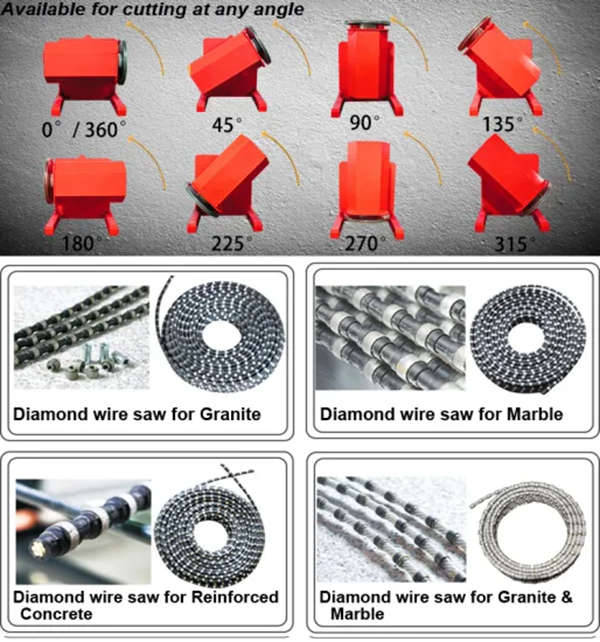

Types of Drive Wheels for Diamond Wire Saws

Different applications may require different types of drive wheels. Common variations include those designed specifically for wet cutting applications versus dry cutting scenarios. Additionally, the size and material composition of the wheel can vary depending on the intended use. For instance, larger wheels are often used in industrial settings where continuous operation is required, whereas smaller wheels might be more suitable for portable units used in remote locations or tight spaces.

Maintaining the Drive Wheel for Diamond Wire Saw

Proper maintenance is crucial for extending the lifespan of your drive wheel and ensuring consistent performance. Regular inspections should be conducted to check for signs of wear such as cracks or deformities. Lubrication is another critical aspect of maintenance, helping to reduce friction and prevent overheating. By keeping up with routine care, users can minimize downtime and avoid costly repairs or replacements.

Choosing the Right Drive Wheel for Your Diamond Wire Saw

Selecting the appropriate drive wheel depends on several factors including the type of material being cut, the size of the project, and the specific requirements of the job site. Factors such as the diameter of the wheel, its surface texture, and even the material it’s made from play significant roles in determining suitability. Consulting with experienced professionals or manufacturers can provide valuable insights when making these decisions.

Installation of the Drive Wheel for Diamond Wire Saw

Correct installation of the drive wheel is essential for safe and effective operation. This process typically involves aligning the wheel correctly within the frame of the saw and ensuring that all connections are secure. Special attention must be paid to achieving the right amount of tension in the wire, which directly impacts cutting accuracy and speed. Following manufacturer guidelines closely during installation helps guarantee optimal performance.

Troubleshooting Issues with the Drive Wheel for Diamond Wire Saw

Despite best efforts in maintenance and proper usage, issues can arise over time. Common problems might include slippage, excessive noise, or decreased cutting efficiency. Identifying the root cause of these issues often requires a systematic approach, starting with visual inspections and moving on to more detailed diagnostic tests if necessary. Quick action to address any anomalies can prevent minor issues from escalating into major breakdowns.

By focusing on the drive wheel for diamond wire saws, professionals in the construction industry can ensure they’re equipped with the tools necessary to tackle even the most challenging projects. Whether it’s choosing the right type of wheel, maintaining it properly, or troubleshooting potential problems, attention to detail pays off in terms of both productivity and safety.

Request for Quotation

报错: 未找到这个表单