The Releated Products of Dremel Ceramic Cutter

Dremel Ceramic Cutter

Table of Contents

Dremel Ceramic Cutter: Precision and Versatility for Your DIY Projects

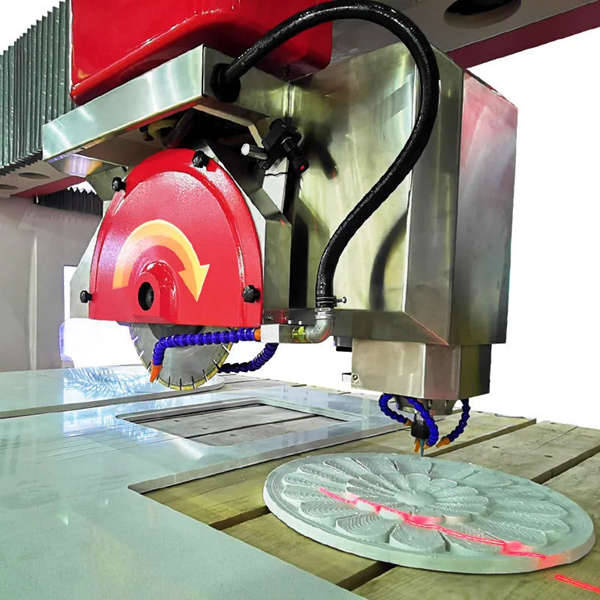

When it comes to cutting ceramics, precision and control are paramount. This is where the Dremel Ceramic Cutter shines, offering DIY enthusiasts and professionals alike a reliable tool for their projects. With its ergonomic design and high-performance features, this tool stands out as a must-have for anyone looking to achieve clean, accurate cuts in ceramic tiles.

Dremel Ceramic Cutter: An Overview

The Dremel Ceramic Cutter is designed to provide a seamless experience when working with ceramic materials. Its robust construction ensures durability while its adjustable depth settings allow for precise control over the cutting process. Whether you’re a seasoned craftsman or just starting out, the Dremel Ceramic Cutter simplifies your workflow, making complex projects more manageable.

Key Features of the Dremel Ceramic Cutter

Understanding the key features of the Dremel Ceramic Cutter can help you leverage its full potential. Some notable aspects include:

– Adjustable Depth: This feature allows users to set the depth of the cut accurately, reducing the risk of chipping or cracking.

– Ergonomic Design: The tool is designed to fit comfortably in your hand, reducing strain during extended use.

– Versatility: Ideal not only for ceramics but also suitable for cutting glass, porcelain, and other similar materials.

These features make the Dremel Ceramic Cutter a versatile addition to any workshop, capable of handling a wide range of tasks efficiently.

How to Use the Dremel Ceramic Cutter

Using the Dremel Ceramic Cutter effectively requires some basic knowledge and practice. Here’s a quick guide to get you started:

1. Prepare Your Workspace: Ensure that your work area is clean and well-lit. Secure the ceramic piece firmly on a flat surface.

2. Adjust the Depth: Depending on the thickness of the material, adjust the cutting depth accordingly.

3. Score the Surface: Gently run the cutter along the marked line to score the surface of the ceramic.

4. Break Along the Score: Apply pressure to break the tile along the scored line, ensuring a clean break.

By following these steps, you can achieve precise cuts every time, enhancing the quality of your finished projects.

Benefits of Using the Dremel Ceramic Cutter

Investing in a Dremel Ceramic Cutter brings numerous benefits to your DIY endeavors:

– Precision Cutting: Achieve clean, straight cuts with minimal effort.

– Time Efficiency: Get projects done faster due to the tool’s speed and ease of use.

– Cost-Effective: Compared to hiring professionals, using a Dremel Ceramic Cutter can save you money in the long run.

These advantages make the Dremel Ceramic Cutter a valuable investment for both hobbyists and professionals seeking high-quality results.

Maintenance Tips for Your Dremel Ceramic Cutter

To ensure longevity and optimal performance, regular maintenance is essential. Here are some tips to keep your Dremel Ceramic Cutter in top condition:

– Clean After Each Use: Wipe down the tool to remove any debris or dust.

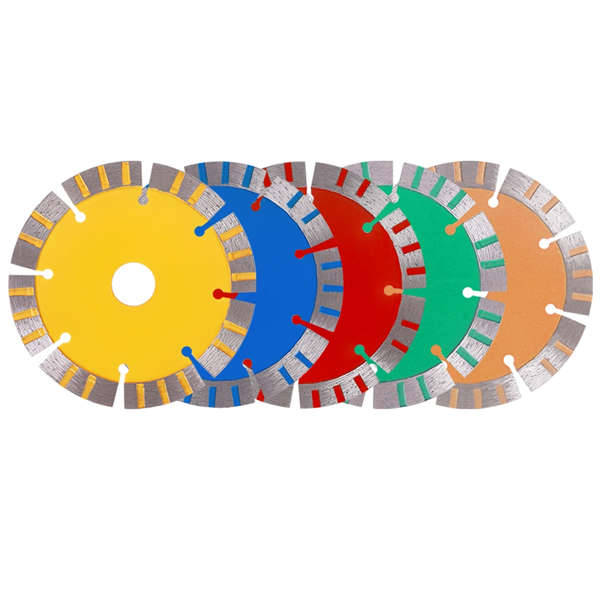

– Check for Wear: Regularly inspect the blade for signs of wear and replace if necessary.

– Store Properly: Keep the tool in a dry place away from moisture and extreme temperatures.

Following these simple maintenance practices will help extend the life of your Dremel Ceramic Cutter, ensuring it remains a reliable tool in your arsenal.

In conclusion, the Dremel Ceramic Cutter offers a combination of precision, versatility, and user-friendliness that makes it indispensable for tackling various ceramic cutting tasks. Whether you’re renovating your home or creating intricate art pieces, this tool delivers the performance you need to bring your visions to life.

Request for Quotation

报错: 未找到这个表单