The Releated Products of Diamond Wire Saw Tool

Diamond Wire Saw Tool

Table of Contents

Diamond Wire Saw: A Precision Cutting Tool for Tough Materials

In the realm of industrial cutting, precision and efficiency are paramount. One tool that has revolutionized the way we approach challenging materials is the diamond wire saw. This advanced machinery offers unparalleled accuracy and versatility, making it indispensable in various sectors including construction, mining, and stonework. Let’s delve deeper into what makes the diamond wire saw such a powerful asset.

What Is a Diamond Wire Saw Tool?

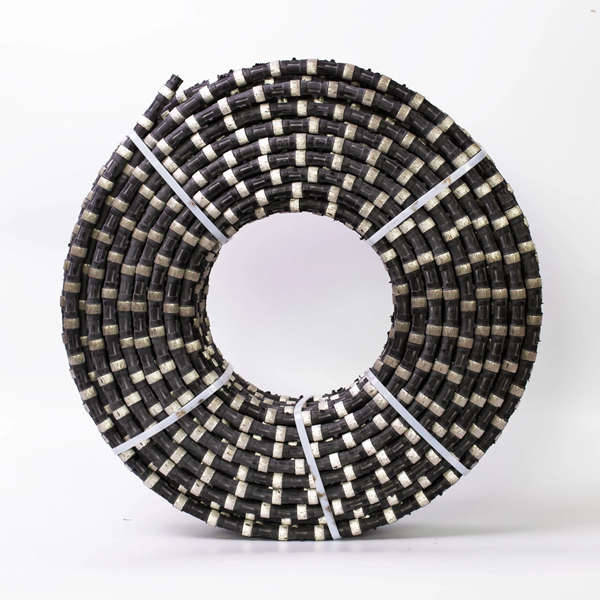

A diamond wire saw tool is essentially a thin, flexible cable embedded with diamond grains. These grains act as cutting edges, allowing the wire to slice through materials like concrete, stone, and even reinforced metals with minimal effort. The continuous loop design ensures consistent cutting pressure and reduces wear on the wire, extending its lifespan significantly.

How Does a Diamond Wire Saw Work?

Understanding how a diamond wire saw works is crucial for maximizing its potential. The process begins by threading the wire through guide pulleys positioned around the material to be cut. Water is then used to cool the wire and flush away debris, maintaining optimal cutting conditions. As the motor drives the wire at high speeds, the embedded diamonds grind against the surface, creating precise cuts with minimal vibration or noise compared to traditional methods.

Benefits of Using Diamond Wire Saws

The advantages of using a diamond wire saw extend far beyond its cutting capabilities. One major benefit is its ability to make controlled cuts in areas where traditional saws cannot reach. This includes cutting below ground level or within confined spaces. Additionally, because it produces less dust and noise pollution, it can be used in environments sensitive to these factors, such as hospitals or residential areas.

Applications of Diamond Wire Saw Tools

From bridge demolition to quarrying precious stones, the applications of diamond wire saw tools are vast. In construction, they are invaluable for removing sections of damaged concrete without disturbing surrounding structures. In the mining industry, these saws enable precise extraction of minerals while minimizing waste. For artisans working with marble or granite, diamond wire saws provide a means of achieving clean, straight edges without chipping or cracking the material.

Maintenance and Care of Your Diamond Wire Saw

To ensure longevity and continued performance, proper maintenance of your diamond wire saw is essential. Regular inspection of the wire for signs of wear or damage is critical. Cleaning the machine thoroughly after each use helps prevent buildup of debris which could interfere with operation. Lubricating moving parts regularly also contributes to smoother functioning and extends the life of your equipment.

Choosing the Right Diamond Wire Saw for Your Needs

Selecting the appropriate diamond wire saw depends largely on the specific requirements of your project. Factors such as the hardness of the material being cut, the depth of the cut required, and the size of the work area all play into this decision. Consulting with experts in the field or manufacturers can provide valuable insights into choosing the most suitable model for your application.

In conclusion, the diamond wire saw stands out as a versatile and efficient solution for tackling tough cutting jobs across multiple industries. Its unique features make it a preferred choice among professionals looking for accuracy, speed, and reliability. Whether you’re involved in large-scale construction projects or detailed stonemasonry, investing in a quality diamond wire saw could very well be the key to unlocking new levels of productivity and craftsmanship.

Request for Quotation

报错: 未找到这个表单