The Releated Products of Diamond Wire Saw Stone Cutting Factory

Diamond Wire Saw Stone Cutting Factory

Diamond Wire Saw Stone Cutting Factory: Precision and Efficiency in Modern Stonework

In the heart of the industrial sector, where innovation meets tradition, lies the diamond wire saw stone cutting factory—a testament to advanced technology and craftsmanship. This facility specializes in using diamond wire saws for cutting various types of stones, from granite and marble to limestone and sandstone. With a focus on precision, efficiency, and sustainability, these factories have become indispensable in the world of construction and architecture.

The Evolution of Diamond Wire Saws in Stone Cutting Factories

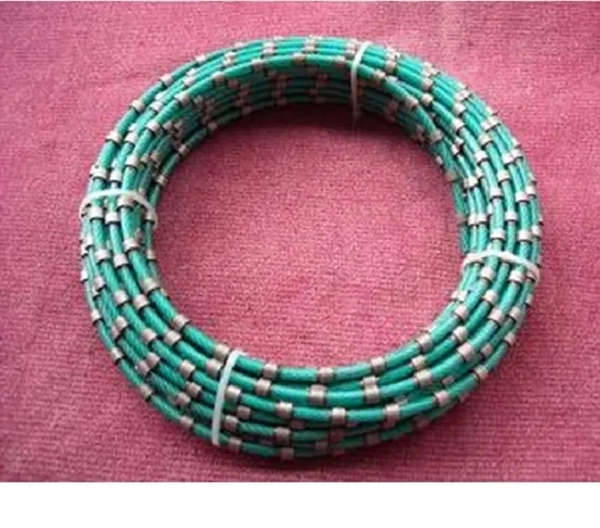

The introduction of diamond wire saws has revolutionized the stone cutting industry. These saws consist of a thin metal cable embedded with diamond grains, which can cut through hard materials like stone with remarkable ease. Unlike traditional methods that often lead to significant waste and uneven cuts, diamond wire saws offer unparalleled accuracy and minimal material loss. This advancement not only speeds up the production process but also ensures higher quality products.

Benefits of Using Diamond Wire Saws in Stone Cutting

Diamond wire saws provide several advantages over conventional stone cutting tools. They enable cleaner, smoother cuts, reducing the need for further finishing processes. Additionally, they operate with less noise and vibration, creating a safer working environment. The ability to cut continuously without stopping also enhances productivity, making them ideal for large-scale projects requiring high volumes of precisely cut stones.

Process of Diamond Wire Saw Cutting in the Factory

A typical day at a diamond wire saw stone cutting factory begins with selecting the appropriate wire saw for the job based on the type and hardness of the stone. Once chosen, the saw is set up on a machine that guides it along the predetermined path for cutting. Operators monitor the process closely, ensuring optimal performance and maintaining the integrity of both the equipment and the material being cut. Water is sprayed onto the cutting area to cool the wire and suppress dust, contributing to a cleaner workspace.

Applications of Diamond Wire Saw Cut Stones

Products manufactured in diamond wire saw stone cutting factories find applications across multiple industries. In construction, these stones are used for flooring, countertops, facades, and sculptures. The automotive industry benefits from lightweight yet durable components made from specially treated stones. Even artistic creations such as statues and monuments rely on the precise cuts provided by diamond wire saws to achieve their intricate designs.

Sustainability Practices in Diamond Wire Saw Stone Cutting

Environmental consciousness plays a crucial role in modern manufacturing practices. Diamond wire saw stone cutting factories implement sustainable strategies to minimize their ecological footprint. This includes recycling water used during the cutting process, reusing abrasive materials, and optimizing energy consumption. By adopting green initiatives, these facilities contribute positively to environmental conservation efforts while maintaining high standards of production quality.

Future Innovations in Diamond Wire Saw Technology

As technology continues to evolve, so too does the potential for diamond wire saws. Research is ongoing into developing stronger, more durable diamond grains and enhancing the flexibility of the wire itself. These improvements promise even greater precision and faster cutting speeds, setting the stage for exciting advancements in the stone cutting industry. As we look ahead, it’s clear that diamond wire saw stone cutting factories will remain at the forefront of innovation, driving growth and excellence in the field of stonework.

Request for Quotation

报错: 未找到这个表单