The Releated Products of Diamond Wire Saw Quarry

Diamond Wire Saw Quarry

Table of Contents

Diamond Wire Saw Quarry: Precision in Stone Extraction

In the world of stone extraction, precision and efficiency are paramount. One technology that has revolutionized this industry is the diamond wire saw quarry. This method offers unparalleled accuracy and speed, transforming the way quarries operate globally.

Diamond Wire Saw Quarry: An Overview

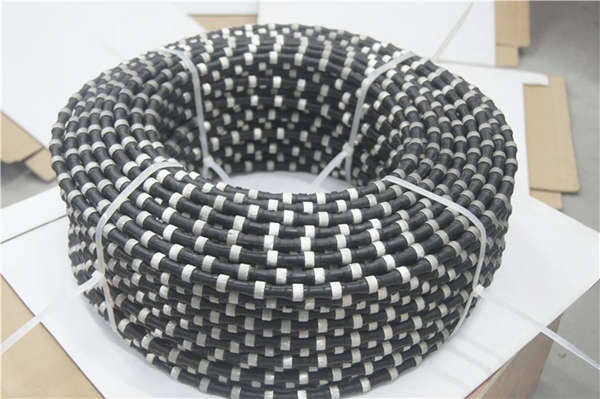

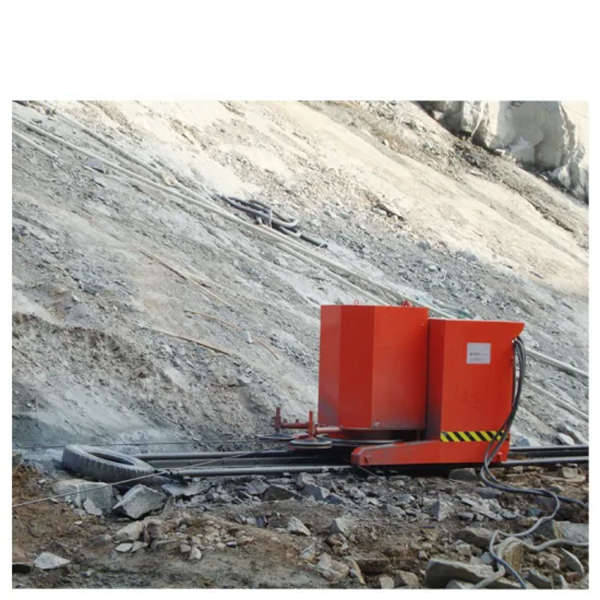

The diamond wire saw quarry process involves using a thin, flexible wire embedded with diamond grains to cut through rock. This method is highly versatile, capable of cutting virtually any type of stone, including granite, marble, and limestone. Unlike traditional methods such as flame cutting or plug and feather techniques, diamond wire sawing produces minimal noise and vibration, reducing the risk of damage to surrounding structures.

Benefits of Diamond Wire Saw Quarry

One of the most significant advantages of using a diamond wire saw quarry is its ability to achieve clean, precise cuts. This results in higher quality stone slabs with fewer cracks or chips. Additionally, because the process is water-cooled, it minimizes dust production, creating a safer working environment for quarry workers. Furthermore, the ability to make curved or angled cuts opens up new possibilities in architectural designs, making the diamond wire saw quarry an indispensable tool for modern construction projects.

Applications of Diamond Wire Saw Quarry

From large-scale commercial projects to intricate artistic works, the applications of diamond wire saw quarry technology are extensive. It is particularly useful for extracting large blocks of stone required for building facades, sculptures, and countertops. In restoration work, where preserving historical integrity is crucial, the precision offered by diamond wire saws allows for careful removal and replacement of damaged sections without affecting adjacent areas.

Environmental Impact of Diamond Wire Saw Quarry

While traditional quarrying methods can be quite destructive to the environment, diamond wire saw quarry practices are more sustainable. They produce less waste material and require less energy compared to other cutting techniques. The reduction in noise pollution also makes these operations more acceptable in populated areas, reducing conflicts between quarry operators and local communities.

Maintenance and Operation of Diamond Wire Saw Quarry Equipment

To ensure optimal performance and longevity of diamond wire saw quarry machinery, regular maintenance is essential. This includes inspecting the wire for wear and tear, checking lubrication levels, and ensuring that all safety features are functioning correctly. Operators must receive thorough training to handle the equipment safely and efficiently, maximizing productivity while minimizing risks.

Future Prospects for Diamond Wire Saw Quarry Technology

As technology continues to advance, so too does the potential of diamond wire saw quarry systems. Innovations in materials science are leading to the development of stronger, more durable wires capable of cutting through even harder stones with ease. Additionally, automation and robotics are being integrated into the process, enhancing accuracy and speed further. These advancements promise to make diamond wire saw quarry operations even more efficient and cost-effective in the years to come.

Diamond wire saw quarry technology represents a significant leap forward in the field of stone extraction. Its benefits in terms of precision, versatility, and environmental sustainability make it a preferred choice for many quarry operators worldwide. As research and development continue, we can expect this method to play an increasingly important role in shaping the future of the stone industry.

Request for Quotation

报错: 未找到这个表单