The Releated Products of Diamond Wire Saw Quarry Factory

Diamond Wire Saw Quarry Factory

Diamond Wire Saw Quarry Factory: Precision and Efficiency in Stone Extraction

The Evolution of Diamond Wire Saws in Quarry Factories

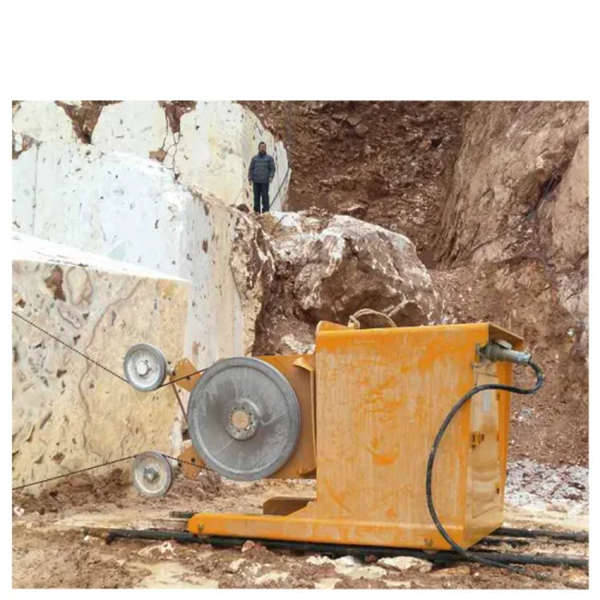

In the realm of stone extraction, diamond wire saws have revolutionized the industry by offering unparalleled precision and efficiency. Unlike traditional methods that relied on explosives or drills, diamond wire saw technology provides a cleaner, more controlled method for cutting through hard materials such as granite, marble, and limestone. This advancement not only enhances productivity but also minimizes waste and environmental impact, making it a preferred choice among modern quarry factories.

Benefits of Using Diamond Wire Saws in Quarry Operations

The introduction of diamond wire saws into quarry operations has brought about numerous benefits that contribute significantly to the overall performance and sustainability of these facilities. One major advantage is the ability to achieve precise cuts with minimal vibration, which reduces the risk of damage to the surrounding rock structure. Additionally, water is used during the cutting process to cool the wire and suppress dust, leading to a safer working environment and better air quality.

How Diamond Wire Saw Technology Works in Quarry Factories

Understanding how diamond wire saw technology operates within a quarry factory is essential for appreciating its capabilities and limitations. Essentially, a thin steel cable embedded with industrial diamonds rotates at high speeds under tension, effectively slicing through stone with remarkable accuracy. The continuous loop design allows for uninterrupted cutting, even around complex shapes and contours, making it ideal for extracting blocks of various sizes and dimensions from quarries.

Maintenance Requirements for Diamond Wire Saws in Quarry Factories

To ensure optimal performance and longevity of diamond wire saws used in quarry settings, regular maintenance is crucial. This includes inspecting the wire for wear and tear, checking the tensioning system, and replacing worn components as needed. Proper lubrication of moving parts and ensuring a steady supply of clean water for cooling purposes are also vital aspects of maintaining these sophisticated tools. By adhering to recommended maintenance schedules, quarry operators can maximize the return on investment while minimizing downtime.

Environmental Impact of Diamond Wire Saws in Quarry Factories

One often overlooked aspect of adopting diamond wire saw technology in quarry factories is its positive environmental impact. Compared to conventional blasting techniques, this method generates less noise pollution and produces fewer harmful emissions. Moreover, because it allows for selective extraction, there is less overburden removal required, thus reducing the overall footprint of quarry operations. These factors contribute to a more sustainable approach to stone mining that aligns well with growing global efforts towards greener manufacturing practices.

Future Prospects for Diamond Wire Saw Quarry Factories

As technology continues to evolve, so too will the capabilities and applications of diamond wire saws in quarry factories. Innovations such as automation and remote operation systems promise to further enhance safety, efficiency, and cost-effectiveness. Furthermore, ongoing research into developing stronger, longer-lasting diamond segments could lead to even more durable saws capable of tackling harder materials. With these advancements on the horizon, the future looks bright for those invested in state-of-the-art stone extraction technologies.

Request for Quotation

报错: 未找到这个表单