The Releated Products of Diamond Wire Saw Marble

Diamond Wire Saw Marble

Table of Contents

Diamond Wire Saw Marble: Precision Cutting for Timeless Beauty

In the world of stone cutting, precision and efficiency are paramount. One tool that has revolutionized the industry is the diamond wire saw. Specifically designed for cutting marble, this technology offers unparalleled accuracy and speed. Whether you’re involved in construction, sculpture, or any form of stonework, understanding how diamond wire saws work can significantly enhance your projects involving marble.

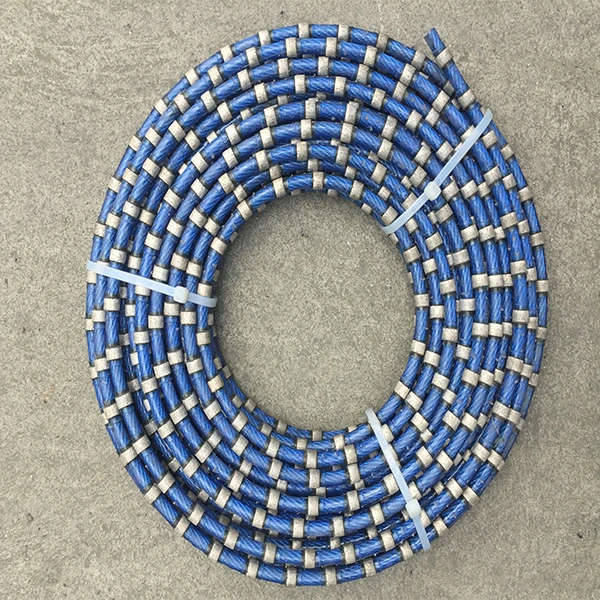

Diamond Wire Saw Marble: How It Works

A diamond wire saw consists of a thin metal wire embedded with diamond grains. As the wire moves through the marble, these diamonds act as cutting edges, gradually slicing through the material. The process is not only efficient but also allows for complex shapes and designs that would be difficult to achieve with traditional methods. This makes it ideal for architects and artists seeking unique forms from their marble pieces.

Benefits of Using Diamond Wire Saw on Marble

The advantages of using a diamond wire saw for marble are numerous. First, it ensures clean cuts with minimal chipping or cracking. This is crucial when working with high-value materials like marble, where every inch counts. Additionally, the ability to cut at various angles and depths opens up new possibilities in design and functionality. Lastly, the reduced noise and dust production compared to other cutting methods make it environmentally friendly and safer for workers.

Applications of Diamond Wire Saw Marble

From monumental structures to intricate sculptures, the applications of diamond wire saws in marble cutting are vast. In construction, they enable precise cutting of marble slabs for flooring, walls, and countertops. For sculptors, the technology provides the means to bring their artistic visions to life by allowing them to carve detailed features into marble blocks. Furthermore, restoration projects benefit greatly from this technology due to its ability to preserve the integrity of historical marble elements while making necessary adjustments.

Maintenance and Care of Diamond Wire Saws Used on Marble

To ensure longevity and optimal performance of your diamond wire saw, proper maintenance is essential. Regular cleaning of the wire helps remove debris that can dull the cutting surface over time. Lubricating moving parts reduces wear and tear, extending the machine’s lifespan. Lastly, storing the saw in a dry place prevents rusting and corrosion, which could compromise its effectiveness.

Choosing the Right Diamond Wire Saw for Marble Projects

Selecting the appropriate diamond wire saw depends on several factors, including the size of your project, the hardness of the marble being cut, and your budget. Larger projects might require industrial-grade saws capable of handling extended use and tougher materials. Smaller, more detailed works may benefit from handheld versions offering greater control. Consulting with experts or suppliers familiar with your specific needs can help guide you towards the best option for your requirements.

Future Innovations in Diamond Wire Saw Marble Technology

As technology advances, so too does the potential of diamond wire saws in marble cutting. Research is ongoing to develop even stronger diamond compounds, longer-lasting wires, and more efficient motors. These innovations promise to further improve the precision, speed, and durability of diamond wire saws, making them indispensable tools for anyone working with marble in the years to come.

Diamond wire saws represent a significant leap forward in marble cutting technology, offering unmatched precision, versatility, and efficiency. By staying informed about advancements in this field and choosing the right equipment for your needs, you can ensure that your marble projects meet the highest standards of quality and craftsmanship.

Request for Quotation

报错: 未找到这个表单