The Releated Products of Diamond Wire Saw Machine Quarry

Diamond Wire Saw Machine Quarry

Diamond Wire Saw Machine Quarry: Precision Cutting in Stone Extraction

In the dynamic world of stone quarrying, precision and efficiency are paramount. The advent of diamond wire saw machines has revolutionized how quarries operate, enhancing both safety and productivity. This article delves into the intricacies of diamond wire saw machine quarry operations, exploring their benefits, applications, and future prospects.

Efficiency in Diamond Wire Saw Machine Quarry Operations

One of the most significant advantages of using diamond wire saws in quarries is their unparalleled efficiency. Unlike traditional methods that rely on explosives or mechanical wedges, diamond wire saws cut through stone with minimal waste and reduced noise pollution. The continuous cutting action of these machines allows for faster extraction rates, significantly improving the overall throughput of a quarry.

Environmental Impact of Diamond Wire Saw Machine Quarry Practices

Environmental sustainability is increasingly becoming a critical consideration in industrial practices, including stone quarrying. Diamond wire saw machine quarry techniques stand out due to their lower environmental footprint compared to conventional blasting methods. These machines produce less dust and vibration, contributing positively to air quality and reducing the risk of damage to nearby structures.

Safety Enhancements in Diamond Wire Saw Machine Quarry Work

Safety remains a top priority in any industrial setting, particularly in quarries where heavy machinery and hazardous conditions are common. Diamond wire saw machine quarry operations have been lauded for their ability to improve workplace safety. By minimizing the use of explosives, these machines reduce the risks associated with blasting, such as fly-rock and ground instability.

Cost-Effectiveness of Adopting Diamond Wire Saw Machine Quarry Solutions

While the initial investment in diamond wire saw technology might seem substantial, the long-term cost-effectiveness of these systems cannot be overstated. They offer higher yields from each block of stone due to precise cutting, which translates into better material utilization. Additionally, reduced downtime and maintenance costs contribute to making diamond wire saw machine quarry operations economically viable.

Technological Advancements in Diamond Wire Saw Machine Quarry Equipment

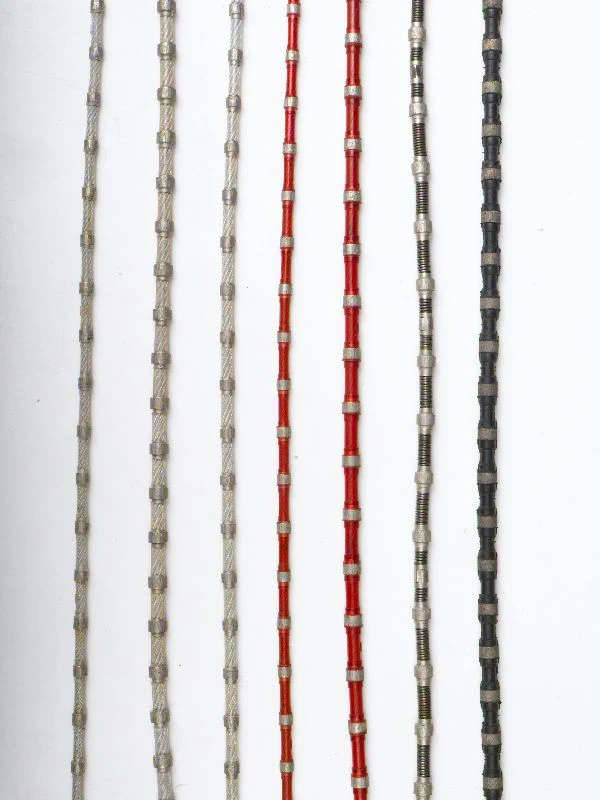

The ongoing evolution of diamond wire saw technology continues to push the boundaries of what’s possible in stone extraction. Innovations in blade design, motor efficiency, and automation are leading to more robust and versatile machines. These advancements ensure that diamond wire saw machine quarry processes remain at the forefront of sustainable and efficient stone harvesting.

Future Prospects for Diamond Wire Saw Machine Quarry Industries

Looking ahead, the future of diamond wire saw machine quarry operations looks promising. As the demand for high-quality stone products increases globally, so too does the need for advanced extraction technologies. Continued research and development in this field will likely lead to even more efficient and eco-friendly solutions, further solidifying the role of diamond wire saws in modern quarrying practices.

By embracing the capabilities of diamond wire saw machine quarry technology, operators can achieve new levels of performance, sustainability, and profitability. As we move forward, it’s clear that these innovative tools will play a pivotal role in shaping the future of the stone quarry industry.

Request for Quotation

报错: 未找到这个表单