The Releated Products of Diamond Wire Saw Machine Aluminium Wheel

Diamond Wire Saw Machine Aluminium Wheel

Table of Contents

Diamond Wire Saw Machine Aluminium Wheel: Precision Engineering for Advanced Cutting Applications

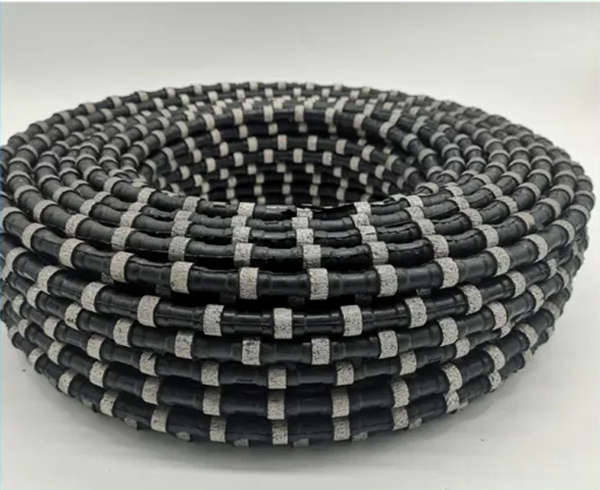

In the realm of industrial cutting technologies, diamond wire saw machines equipped with aluminium wheels have emerged as indispensable tools. These machines combine the precision of diamond wires with the robustness of aluminium wheels, offering unparalleled efficiency and durability. This article delves into the key features, applications, and benefits of diamond wire saw machine aluminium wheels, highlighting why they are a preferred choice across various industries.

The Superiority of Aluminium Wheels in Diamond Wire Saws

Aluminium wheels play a critical role in enhancing the performance of diamond wire saws. Known for their lightweight yet sturdy construction, these wheels reduce the overall weight of the sawing system, improving maneuverability and reducing energy consumption. Moreover, aluminium’s resistance to corrosion ensures longer wheel life, even when used in harsh environments or with abrasive materials. The use of aluminium wheels also facilitates faster cutting speeds and smoother operation, making them ideal for intricate and large-scale projects alike.

Enhanced Cutting Precision with Diamond Wire Saw Machine Aluminium Wheel

Precision is paramount in industries such as construction, mining, and manufacturing. Diamond wire saw machine aluminium wheels deliver this precision by providing stable support to the wire during cutting processes. The precise alignment of the wire on the aluminium wheel minimizes deflection, ensuring clean, straight cuts. This level of accuracy is crucial when working with delicate or complex materials where any deviation can lead to significant waste or compromised structural integrity.

Cost-Effectiveness of Utilizing Diamond Wire Saw Machine Aluminium Wheel

While the initial investment in a diamond wire saw machine with aluminium wheels may be higher compared to traditional sawing systems, the long-term cost savings are substantial. The durability of aluminium reduces the frequency of wheel replacements, lowering maintenance costs over time. Additionally, the efficiency gains from faster cutting speeds translate into increased productivity and reduced labor costs. These factors combined make diamond wire saw machines with aluminium wheels a cost-effective solution for businesses looking to enhance their cutting capabilities without inflating operational expenses.

Adaptability of Diamond Wire Saw Machine Aluminium Wheel Across Industries

One of the most compelling aspects of diamond wire saw machine aluminium wheels is their versatility. Whether it’s cutting through reinforced concrete in construction sites, slicing through granite in quarries, or processing silicon wafers in semiconductor fabrication plants, these machines adapt seamlessly to diverse requirements. The ability to handle a wide range of materials makes them a versatile tool, capable of meeting the specific needs of different industries with minimal adjustments.

Maintenance Requirements for Diamond Wire Saw Machine Aluminium Wheel

To ensure optimal performance and longevity, regular maintenance is essential for diamond wire saw machine aluminium wheels. This includes inspecting the wheels for wear and tear, cleaning debris from the grooves, and lubricating moving parts. Regular maintenance not only extends the life of the equipment but also helps in maintaining consistent cutting quality. Manufacturers often provide detailed guidelines on recommended maintenance schedules and procedures, which should be followed closely to avoid premature wear and potential safety hazards.

Innovations in Diamond Wire Saw Machine Aluminium Wheel Technology

As technology advances, so do the capabilities of diamond wire saw machines with aluminium wheels. Innovations such as advanced cooling systems, improved diamond wire designs, and more efficient drive mechanisms continue to push the boundaries of what these machines can achieve. New developments focus on increasing cutting speed, enhancing accuracy, and reducing noise levels, all while maintaining or improving upon the existing high standards of safety and environmental impact. As research progresses, we can expect to see even more sophisticated solutions that will further revolutionize industrial cutting practices.

By integrating the latest advancements in material science and engineering design, diamond wire saw machine aluminium wheels are setting new benchmarks in performance and reliability. Their widespread adoption across multiple sectors underscores their value as a cornerstone technology in modern cutting operations.

Request for Quotation

报错: 未找到这个表单