The Releated Products of Diamond Wire Saw For Silicon

Diamond Wire Saw For Silicon

Diamond Wire Saw for Silicon: Precision Cutting in Semiconductor Manufacturing

In the rapidly evolving landscape of semiconductor manufacturing, precision and efficiency are paramount. One tool that has revolutionized silicon wafer slicing is the diamond wire saw. This advanced technology offers unparalleled accuracy and speed, making it indispensable in the industry. Let’s delve into how this innovative machinery operates and its benefits within silicon processing.

Diamond Wire Saw for Silicon: An Overview

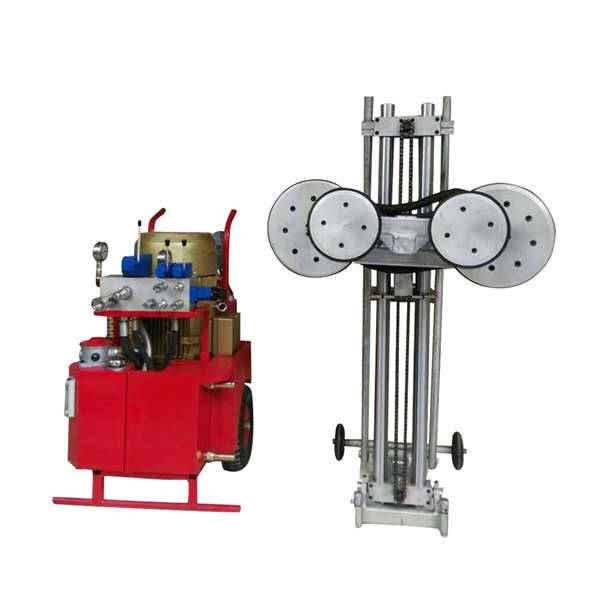

A diamond wire saw consists of a thin metal wire embedded with minute diamond particles along its length. These abrasive diamonds act as cutting edges, enabling the saw to slice through hard materials like silicon with minimal force. The process begins by threading the wire through a series of guide rollers, which maintain tension and ensure straight cuts. As the wire moves at high speeds, it is guided over the silicon block, gradually slicing it into thin wafers used in electronics.

Advantages of Using a Diamond Wire Saw for Silicon

The adoption of diamond wire saws in silicon manufacturing has brought several advantages over traditional blade-based methods. Firstly, these saws produce thinner kerf widths, reducing material loss and increasing yield per silicon ingot. Additionally, they operate at much faster speeds, significantly boosting production rates. Lastly, because the wire does not contact the workpiece with as much force as a solid blade, there is less risk of damaging the delicate silicon structure during cutting.

How Does a Diamond Wire Saw for Silicon Work?

Understanding the mechanics behind a diamond wire saw helps illustrate why it’s so effective for silicon slicing. The key lies in the combination of the wire’s high-speed motion and the abrasive nature of the diamond particles. When activated, the wire oscillates back and forth while being fed forward through the silicon. This action, combined with a continuous flow of cooling fluid, ensures precise, clean cuts without overheating or chipping the silicon.

Maintenance and Care for Diamond Wire Saws for Silicon

To keep diamond wire saws operating at peak performance, regular maintenance is essential. This includes inspecting and replacing worn wires, cleaning debris from guides and rollers, and ensuring proper alignment of all components. Proper lubrication of moving parts also extends the machine’s lifespan and maintains cutting efficiency. By adhering to these guidelines, manufacturers can minimize downtime and maximize productivity.

Applications of Diamond Wire Saws for Silicon in Modern Industry

Beyond basic silicon wafer production, diamond wire saws find applications across various segments of the semiconductor industry. They are crucial for creating photovoltaic cells, where precision and uniformity are critical for maximizing energy conversion efficiency. Moreover, their ability to handle different grades of silicon makes them ideal for research and development, allowing scientists to experiment with new materials and fabrication techniques.

Future Innovations in Diamond Wire Saw Technology for Silicon

As demand grows for smaller, more powerful electronic devices, the need for ever-thinner silicon wafers becomes increasingly important. To meet this challenge, manufacturers are continuously developing new diamond wire saw technologies aimed at achieving even finer kerfs and higher cutting speeds. Research into alternative abrasive materials, improved wire designs, and enhanced automation systems promises to push the boundaries of what’s possible with diamond wire saws, setting the stage for exciting advancements in silicon processing.

Diamond wire saws have proven themselves indispensable tools in modern semiconductor manufacturing, driving innovation and efficiency across the board. As technology continues to evolve, these machines will undoubtedly play a pivotal role in shaping the future of silicon-based electronics.

Request for Quotation

报错: 未找到这个表单