The Releated Products of Diamond Wire Saw For Silicon Slicing

Diamond Wire Saw For Silicon Slicing

Diamond Wire Saw for Silicon Slicing: Precision and Efficiency

In the rapidly evolving landscape of semiconductor manufacturing, the precision and efficiency of silicon slicing processes play a critical role. One tool that has become indispensable in this sector is the diamond wire saw. This advanced technology allows for the precise cutting of silicon wafers, which are essential components in electronic devices. Here, we explore how diamond wire saws enhance the silicon slicing process, contributing to higher yields and better quality products.

Diamond Wire Saw Technology in Silicon Slicing

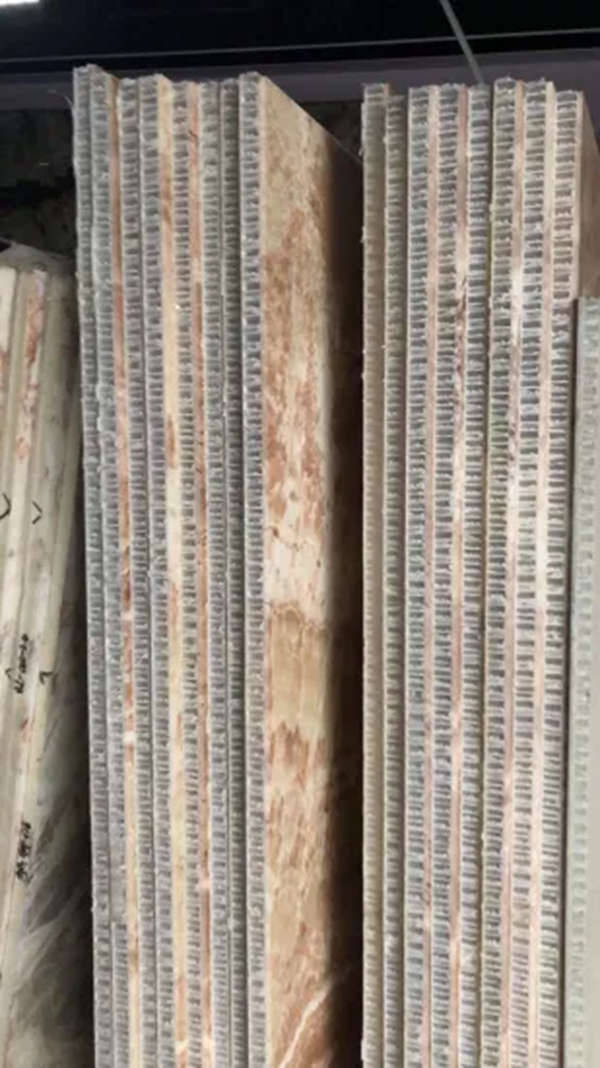

The diamond wire saw technology represents a significant leap forward from traditional methods like blade sawing. It uses a thin wire embedded with diamond particles, capable of making extremely fine cuts through hard materials such as silicon. The use of this technology has led to several improvements in the industry, including reduced material loss during slicing and increased production speed.

Benefits of Using Diamond Wire Saws for Silicon Slicing

One of the key advantages of using diamond wire saws for silicon slicing is their ability to produce thinner kerfs. Thinner kerfs mean less silicon is wasted in the cutting process, leading to substantial cost savings over time. Additionally, these saws can achieve higher cutting speeds without compromising on the quality or integrity of the silicon wafers. This efficiency translates into faster production cycles and potentially lower costs per wafer.

How Diamond Wire Saws Improve Wafer Quality

Another critical aspect where diamond wire saws excel is in maintaining the quality of silicon wafers. Traditional slicing methods often resulted in damaged edges or subsurface damage, which could affect the performance of the final product. With diamond wire saws, the risk of such damage is significantly reduced due to the smoother and cleaner cuts they provide. This improvement in wafer quality directly impacts the reliability and functionality of electronic devices.

Environmental Impact of Diamond Wire Saw in Silicon Slicing

The environmental benefits of adopting diamond wire saw technology for silicon slicing cannot be overlooked. By reducing the amount of silicon waste generated during the cutting process, companies can decrease their overall carbon footprint. Furthermore, since these saws require less energy to operate compared to older technologies, they contribute to lower greenhouse gas emissions, aligning with global sustainability goals.

Future Innovations in Diamond Wire Saw Technology

As research continues into improving silicon slicing techniques, it’s clear that diamond wire saw technology will remain at the forefront of innovation. Ongoing developments aim to further refine the cutting process, focusing on even thinner kerfs, enhanced durability of the saw wires, and more efficient cooling systems. These advancements promise to make silicon slicing not only more precise but also more sustainable in the long run.

Choosing the Right Diamond Wire Saw for Your Needs

Selecting the appropriate diamond wire saw for silicon slicing depends on various factors, including the specific requirements of your manufacturing process, the type of silicon being used, and the desired output. Consulting with experts who specialize in this technology can help ensure you choose a solution that meets all your needs while maximizing efficiency and productivity.

Diamond wire saw technology continues to revolutionize the silicon slicing industry, offering unparalleled precision, efficiency, and sustainability. As manufacturers seek ways to improve their operations and reduce costs, investing in this advanced cutting solution can provide a competitive edge in today’s dynamic semiconductor market.

Request for Quotation

报错: 未找到这个表单