The Releated Products of Diamond Wire Saw For Quarrying

Diamond Wire Saw For Quarrying

Table of Contents

Diamond Wire Saw for Quarrying: Precision and Efficiency in Stone Extraction

In the realm of stone extraction and quarrying, precision and efficiency are paramount. One tool that has revolutionized this industry is the diamond wire saw. This advanced cutting technology offers unparalleled control and speed, making it a preferred choice for quarries worldwide. Let’s delve into the specifics of how diamond wire saws enhance quarrying operations.

Diamond Wire Saw for Quarrying: An Overview

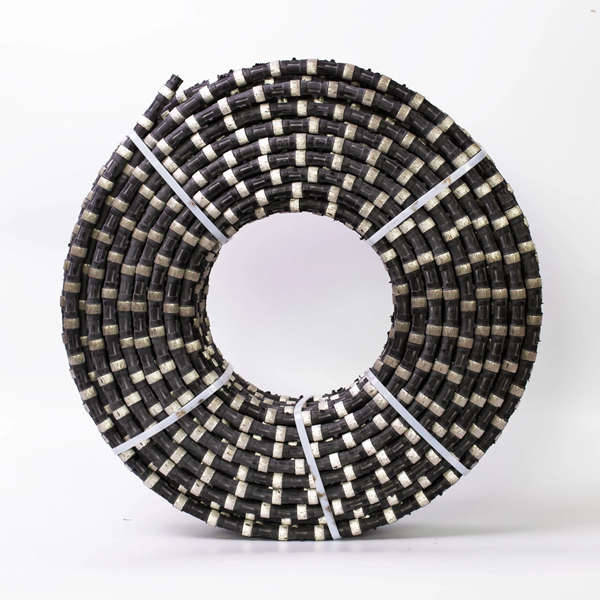

A diamond wire saw consists of a thin metal wire embedded with synthetic diamonds. These diamond particles act as cutting tools, allowing the saw to slice through hard materials like granite, marble, and limestone with ease. The continuous loop design ensures consistent cutting pressure and direction, resulting in smoother cuts compared to traditional methods.

Benefits of Using a Diamond Wire Saw for Quarrying

The use of diamond wire saws in quarrying brings numerous advantages. Firstly, they offer improved accuracy, enabling operators to make precise cuts along predetermined lines. Secondly, these saws produce minimal waste, as they can be guided with great control, reducing material loss during extraction. Additionally, they operate quietly, which is beneficial in noise-sensitive areas, and they create less dust, contributing to a safer work environment.

Applications of Diamond Wire Saws in Quarrying

Diamond wire saws find extensive application in various aspects of quarrying. They are particularly useful for cutting large blocks of stone from the quarry face, ensuring that each piece meets the required specifications. Moreover, they can be employed in the splitting and shaping of stones, offering versatility that traditional methods cannot match.

Maintenance and Care of Diamond Wire Saws for Quarrying

To ensure optimal performance and longevity, proper maintenance of diamond wire saws is essential. Regular inspection for wear and tear, cleaning of the wire to remove debris, and lubrication of moving parts are crucial steps. Proper storage when not in use, ideally in a dry place away from corrosive elements, also helps maintain the integrity of the equipment.

Advancements in Diamond Wire Saw Technology for Quarrying

Technological advancements continue to enhance the capabilities of diamond wire saws. Newer models feature improved diamond segment designs that increase cutting speed and durability. Some incorporate electronic controls that allow for real-time adjustments based on the material being cut, further improving efficiency and reducing operator error. Innovations in wire composition and tensioning systems also contribute to more robust and adaptable saws.

Training and Safety When Using Diamond Wire Saws for Quarrying

Given the power and precision of diamond wire saws, proper training and adherence to safety protocols are vital. Operators must be thoroughly trained on the correct operation, maintenance, and troubleshooting of the equipment. Safety measures, such as wearing protective gear and following established procedures, should be strictly enforced to prevent accidents.

By embracing the use of diamond wire saws, quarries can achieve higher productivity levels while maintaining high standards of quality and safety. As technology continues to evolve, so too will the capabilities and applications of these remarkable tools, ensuring their relevance in the ever-changing landscape of the quarrying industry.

Request for Quotation

报错: 未找到这个表单