The Releated Products of Diamond Wire Saw For Marble

Diamond Wire Saw For Marble

Table of Contents

Diamond Wire Saw for Marble: Precision Cutting at Its Best

In the world of stone cutting and quarrying, precision and efficiency are paramount. One tool that has revolutionized the industry by offering both is the diamond wire saw for marble. This advanced technology enables precise cuts with minimal waste, making it an indispensable asset for any operation dealing with marble. Let’s delve into the details of this remarkable tool and explore its benefits, applications, and considerations.

Diamond Wire Saw for Marble: An Overview

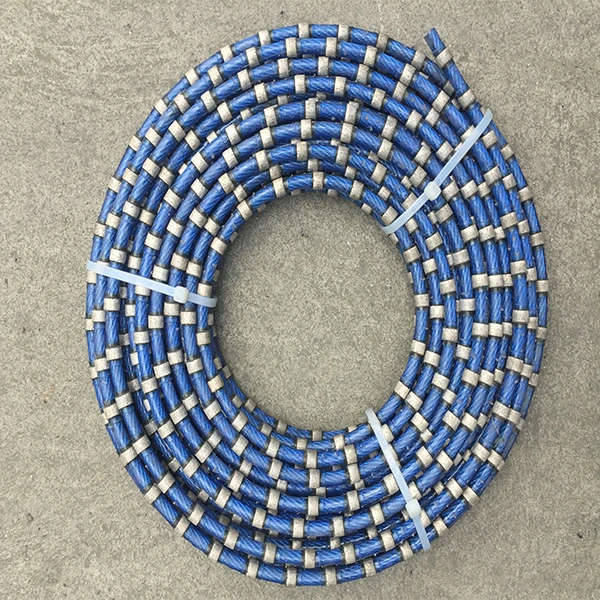

The diamond wire saw for marble is a specialized tool designed specifically for cutting marble and other types of natural stone. It consists of a thin metal cable embedded with diamond grains, which acts as the cutting element. When powered by a motor, this cable moves at high speeds, slicing through the stone with incredible accuracy and smoothness. The continuous loop design ensures consistent performance and allows for cutting large blocks of marble with ease.

Advantages of Using a Diamond Wire Saw for Marble

One of the primary advantages of using a diamond wire saw for marble is its ability to make clean, straight cuts without chipping or damaging the surrounding material. This is particularly important when working with valuable and delicate marble slabs. Additionally, because the wire can be guided precisely, it offers unparalleled control over the cutting process. This leads to higher yields and less material waste compared to traditional methods such as gang saws or circular blades.

Applications of Diamond Wire Saw for Marble

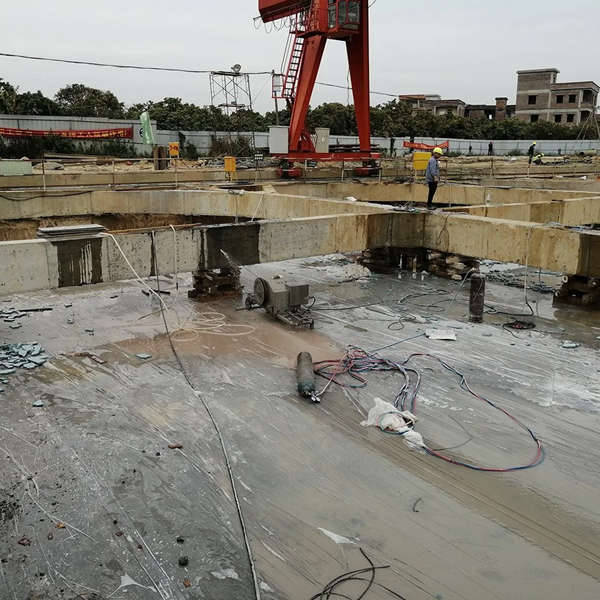

The versatility of the diamond wire saw for marble makes it suitable for various applications within the stone industry. In quarries, it is used to extract large blocks from the earth with minimal effort and maximum efficiency. Once these blocks reach processing facilities, the same tool can be employed to cut them into smaller slabs or tiles. Furthermore, artisans and sculptors often rely on diamond wire saws for marble to create intricate designs and sculptures, taking advantage of the tool’s precision and finesse.

Maintenance and Care of Diamond Wire Saw for Marble

To ensure optimal performance and longevity of your diamond wire saw for marble, proper maintenance is crucial. Regularly inspect the wire for wear or damage, and replace it as necessary to maintain cutting efficiency. Keep the machine clean and lubricated according to the manufacturer’s instructions. Also, store the saw in a dry place when not in use to prevent corrosion and prolong its life.

Selecting the Right Diamond Wire Saw for Marble

When choosing a diamond wire saw for marble, consider factors such as the size of the stones you’ll be cutting, the frequency of use, and your budget. For occasional cutting tasks, a smaller, portable model might suffice. However, if you’re involved in large-scale operations or require frequent use, investing in a more robust industrial-grade unit will likely prove more cost-effective in the long run. Always consult with experts or manufacturers to determine which specifications best meet your needs.

Innovations in Diamond Wire Saw Technology for Marble

As technology advances, so do the capabilities of diamond wire saws for marble. New developments focus on improving speed, reducing noise levels, and enhancing safety features. Some models now incorporate water cooling systems to extend the lifespan of the wire while others feature automatic tensioning mechanisms for easier operation. Staying updated with these advancements can significantly impact productivity and profitability in your business.

By understanding the capabilities and benefits of diamond wire saws for marble, businesses can make informed decisions about incorporating this powerful tool into their operations. Whether you’re a seasoned professional or just starting out in the stone industry, embracing this technology could be the key to unlocking new possibilities and achieving greater success.

Request for Quotation

报错: 未找到这个表单