The Releated Products of Diamond Wire Saw For Granite Factory

Diamond Wire Saw For Granite Factory

Table of Contents

Diamond Wire Saw for Granite: Precision Cutting in Modern Factories

In the bustling heart of granite factories worldwide, one tool stands out for its precision and efficiency: the diamond wire saw. This advanced technology has revolutionized the way granite blocks are cut, offering unparalleled accuracy and speed. As demand for high-quality granite products continues to grow, understanding the capabilities and benefits of diamond wire saws becomes increasingly important.

Diamond Wire Saw for Granite: Efficiency and Speed

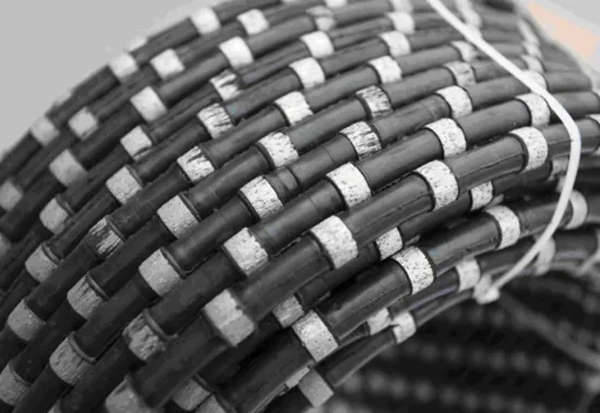

Diamond wire saws are designed specifically to meet the demanding requirements of granite cutting. Unlike traditional methods that rely on circular blades, these saws use a thin, flexible wire embedded with industrial diamonds. This innovative design allows for faster cutting speeds while maintaining exceptional control over the process. In granite factories, this translates to increased productivity and reduced downtime, making it a preferred choice among manufacturers looking to streamline their operations.

Benefits of Using a Diamond Wire Saw for Granite

The adoption of diamond wire saw technology in granite factories offers numerous advantages beyond mere speed. These include improved surface quality of the cut granite, reduced waste, and lower operating costs due to minimal wear and tear on machinery. Additionally, because the sawing process generates less heat compared to traditional methods, there’s a lower risk of thermal damage to the stone. This makes diamond wire saws particularly suitable for cutting delicate or high-value granite slabs.

Environmental Impact of Diamond Wire Saws for Granite Factories

Sustainability is another key factor driving the popularity of diamond wire saws in granite production facilities. By requiring less water for cooling and lubrication during the cutting process, these saws help conserve natural resources. Moreover, they produce smaller quantities of dust and slurry, which are easier to manage and dispose of safely. This not only reduces environmental impact but also contributes to creating healthier working conditions within the factory environment.

Cost-effectiveness of Diamond Wire Saw Technology for Granite Processing

While the initial investment in diamond wire saw technology might seem substantial, the long-term cost savings can be significant. Due to their durability and efficient cutting action, diamond wire saws require less frequent replacement than conventional saw blades. They also consume less energy per cut, leading to lower operational costs over time. For granite factories aiming to optimize their budget without compromising on quality, this technology presents an attractive solution.

Innovations in Diamond Wire Saw Design for Enhanced Performance

As research and development continue in the field of stone cutting equipment, we’re seeing exciting advancements in diamond wire saw designs tailored specifically for granite applications. Newer models feature enhanced diamond grit configurations that improve both cutting speed and edge quality. Some even incorporate smart technologies that allow for real-time monitoring and adjustment of cutting parameters, ensuring consistent performance across various granite types and hardness levels.

Training and Safety Considerations for Diamond Wire Saw Operators in Granite Factories

To fully leverage the capabilities of diamond wire saws, proper training and adherence to safety protocols are essential. Operators must be well-versed in the setup, operation, and maintenance procedures associated with these sophisticated tools. Regular training sessions can help keep staff updated on best practices and emerging trends in diamond wire saw technology. Emphasizing safety measures such as wearing protective gear and following established guidelines helps prevent accidents, ensuring a smooth workflow in granite factories.

By embracing the power of diamond wire saw technology, granite factories can achieve new heights in productivity, sustainability, and product quality. As this trend continues, we can expect to see further innovations that push the boundaries of what’s possible in granite processing.

Request for Quotation

报错: 未找到这个表单