The Releated Products of Diamond Wire Saw For Cutting Marble

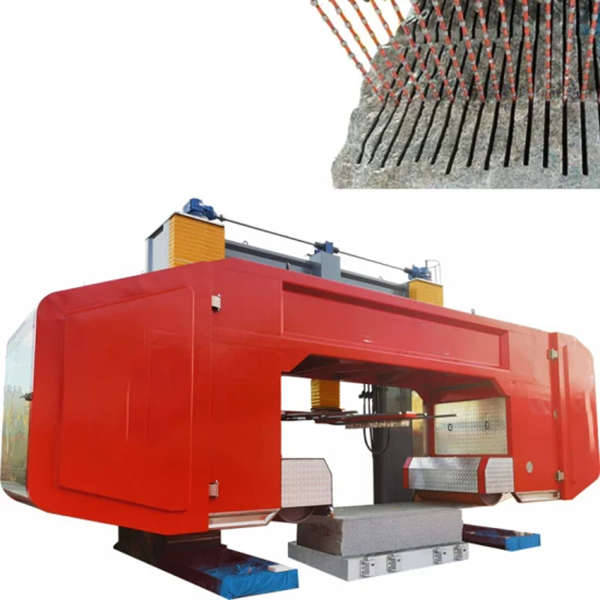

Diamond Wire Saw For Cutting Marble

Diamond Wire Saw for Cutting Marble: Precision and Efficiency

When it comes to cutting marble, precision and efficiency are paramount. This is where diamond wire saws come into play, offering unparalleled accuracy and speed. Whether you’re working on large-scale construction projects or intricate artistic endeavors, these tools can significantly enhance your workflow. Let’s delve deeper into the world of diamond wire saws and explore how they revolutionize the process of cutting marble.

Diamond Wire Saws: An Introduction to Cutting Marble

A diamond wire saw consists of a thin metal cable embedded with industrial diamonds. These diamonds act as the cutting element, allowing the saw to slice through hard materials like marble with ease. The wire is continuously fed by a spool system and guided by pulleys, which keeps it taut during operation. This design not only ensures smooth cuts but also minimizes material waste, making it an eco-friendly choice for many applications.

Benefits of Using Diamond Wire Saws for Cutting Marble

The use of diamond wire saws for cutting marble offers several advantages over traditional methods. Firstly, they provide clean, straight cuts with minimal chipping or cracking. This is particularly beneficial when working with delicate or high-value pieces of marble. Additionally, because the wire can be threaded through small holes, it allows for cutting in confined spaces or around existing structures. Lastly, the reduced noise and dust production compared to other cutting techniques make them ideal for use in residential areas or indoor environments.

How Diamond Wire Saws Work When Cutting Marble

Understanding how a diamond wire saw operates is key to maximizing its potential. As mentioned earlier, the saw uses a thin wire embedded with diamond particles. When powered by a hydraulic motor, this wire moves at high speeds, effectively slicing through the marble. Water is typically used during the cutting process to cool the wire and suppress dust, further contributing to cleaner cuts and a safer work environment.

Applications of Diamond Wire Saws in Cutting Marble

From quarrying large blocks of marble to crafting intricate sculptures, diamond wire saws have become indispensable tools across various industries. In construction, they enable precise cutting of slabs for flooring, countertops, and facades. Artists and sculptors appreciate their ability to achieve detailed and complex designs with ease. Moreover, restoration projects benefit greatly from the precision offered by these saws, ensuring that historical monuments and buildings are carefully maintained without compromising their integrity.

Maintenance and Care of Diamond Wire Saws Used for Cutting Marble

To ensure optimal performance and longevity, proper maintenance of your diamond wire saw is essential. Regular inspection of the wire for wear and tear is crucial, as damaged wires can lead to poor cut quality or even breakage. Lubrication of moving parts and thorough cleaning after each use will help prevent corrosion and extend the life of your tool. Always follow manufacturer guidelines for storage and handling to maintain the efficiency of your diamond wire saw.

Conclusion: Embracing Diamond Wire Saws for Cutting Marble

As we’ve seen, diamond wire saws offer a compelling solution for those involved in marble cutting. Their combination of precision, efficiency, and versatility makes them a valuable addition to any workshop or construction site. By investing in high-quality diamond wire saws and maintaining them properly, professionals can enjoy improved productivity and superior results every time they cut marble. Whether you’re a seasoned craftsman or just starting out, embracing this technology could mark the beginning of a new era in your work with marble.

Request for Quotation

报错: 未找到这个表单