The Releated Products of Diamond Wire Saw For Cutting Manufacturers

Diamond Wire Saw For Cutting Manufacturers

Table of Contents

Diamond Wire Saw for Cutting: Precision and Efficiency in Modern Manufacturing

In the realm of advanced cutting technologies, diamond wire saws have emerged as a game-changer for manufacturers seeking precision, speed, and efficiency. These specialized tools are designed to tackle the most challenging materials with unparalleled accuracy, making them indispensable in industries ranging from construction to semiconductor production. This article explores the world of diamond wire saw manufacturers, highlighting their innovations, applications, and the benefits they bring to various sectors.

Diamond Wire Saw Manufacturers: Pioneering Innovation

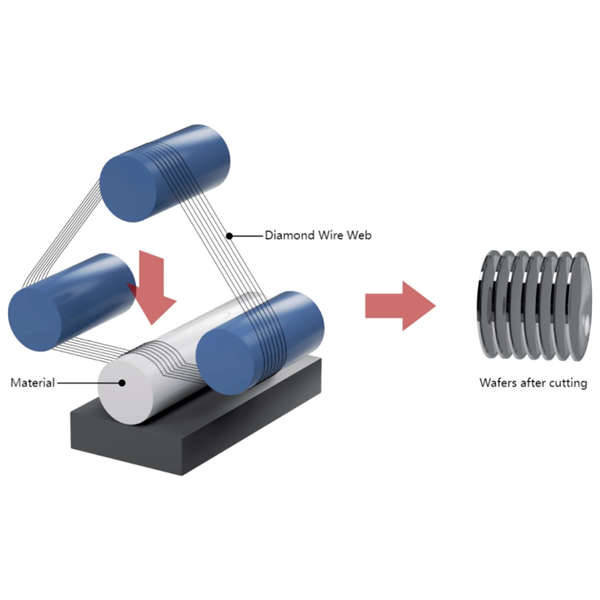

Leading diamond wire saw for cutting manufacturers are constantly pushing the boundaries of what’s possible with this technology. By integrating advanced materials science and engineering principles, these companies develop saws capable of cutting through extremely hard substances like reinforced concrete, granite, and silicon wafers used in electronics. The key to their success lies in the meticulous design and manufacturing processes that ensure durability and performance under demanding conditions.

Applications of Diamond Wire Saws for Cutting

The versatility of diamond wire saws makes them suitable for a wide array of applications across different industries. In construction, they are used for controlled demolition and structural modifications where precision is critical. Semiconductor manufacturers rely on diamond wire saws for slicing thin, delicate wafers with minimal material loss. Similarly, in the gemstone industry, these saws enable jewelers to cut precious stones with finesse, enhancing their beauty and value.

Advantages of Using Diamond Wire Saws for Cutting

Compared to traditional cutting methods, diamond wire saws offer several advantages that make them a preferred choice among professionals. They provide cleaner cuts with smoother edges, reducing the need for post-processing. Additionally, the ability to perform cold cutting (without generating heat) prevents thermal damage to sensitive materials. Another significant benefit is the reduced noise level and dust emission, contributing to safer working environments.

Selecting the Right Diamond Wire Saw Manufacturer

When choosing a diamond wire saw for cutting manufacturer, it’s essential to consider factors such as quality, reliability, and customer support. Reputable manufacturers not only supply top-tier products but also offer technical assistance and training to help users maximize productivity. They continuously invest in research and development to stay ahead of industry trends, ensuring that their clients have access to the latest cutting-edge solutions.

Future Trends in Diamond Wire Saw for Cutting Technology

As technology evolves, so do the capabilities of diamond wire saws. Future advancements are likely to focus on increasing automation and integration into larger manufacturing systems. This will allow for more streamlined processes, improved safety protocols, and even greater precision in cutting operations. Moreover, efforts towards sustainability may lead to the development of eco-friendly materials and practices within the manufacturing sector.

Innovative Solutions from Leading Diamond Wire Saw for Cutting Manufacturers

To meet the diverse needs of customers, leading manufacturers are introducing innovative features in their diamond wire saws. Some innovations include adjustable tension settings for optimal performance across different materials, enhanced durability through improved diamond segment designs, and ergonomic handles for better user comfort during prolonged use. These advancements underscore the commitment of these companies to driving progress in the field of precision cutting.

By focusing on continuous improvement and customer-centric innovation, diamond wire saw for cutting manufacturers continue to shape the future of industrial cutting. Their contributions not only enhance operational efficiency but also pave the way for new possibilities in manufacturing and beyond.

Request for Quotation

报错: 未找到这个表单