The Releated Products of Diamond Wire Saw For Concrete Factory

Diamond Wire Saw For Concrete Factory

Table of Contents

Diamond Wire Saw for Concrete: Precision Cutting Revolutionized

In the realm of construction and demolition, precision cutting has become a necessity more than a luxury. Among the various tools that have transformed this industry, diamond wire saws stand out as a beacon of innovation and efficiency. This article delves into the world of diamond wire saws for concrete factories, exploring their benefits, applications, and how they’re changing the landscape of modern construction.

Diamond Wire Saw for Concrete: Unmatched Precision

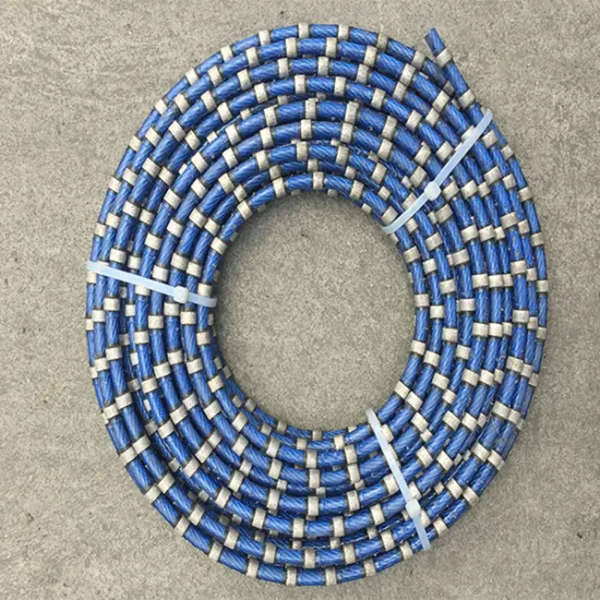

Precision is paramount when it comes to cutting through dense materials like reinforced concrete. A diamond wire saw for concrete offers unparalleled accuracy, thanks to its thin, flexible wire embedded with industrial-grade diamonds. These saws can make cuts where traditional methods would either be too imprecise or completely impractical. Whether it’s cutting through large slabs of concrete or making intricate designs, a diamond wire saw ensures clean, precise cuts every time.

Efficiency of a Diamond Wire Saw for Concrete Operations

Beyond precision, efficiency is another key factor driving the popularity of diamond wire saws in concrete factories. Traditional cutting methods often result in significant downtime due to the need for setup and cleanup. In contrast, diamond wire saws can operate continuously, reducing project timelines and increasing productivity. They also produce minimal dust and noise, making them ideal for use in sensitive environments where traditional cutting methods might not be feasible.

Cost-Effectiveness of Using a Diamond Wire Saw for Concrete

While the initial investment in diamond wire saw technology might seem substantial, the long-term cost-effectiveness makes it a smart choice for concrete factories. The reduced material waste, lower labor costs due to faster cutting times, and decreased maintenance requirements all contribute to a quicker return on investment. Moreover, the ability to cut complex shapes and sizes without compromising structural integrity can lead to savings in design and engineering costs.

Maintenance Requirements of a Diamond Wire Saw for Concrete

Like any piece of heavy machinery, diamond wire saws require regular maintenance to ensure optimal performance and longevity. However, compared to other cutting systems, these saws generally have fewer moving parts, which translates into less frequent maintenance needs. Regular checks on the wire tension, proper lubrication, and timely replacement of worn-out segments are crucial for maintaining the efficiency of a diamond wire saw for concrete operations.

Safety Considerations When Using a Diamond Wire Saw for Concrete

Safety is always a top priority in any industrial setting, especially when dealing with powerful cutting tools. Diamond wire saws come equipped with several safety features designed to protect operators. These include automatic shut-off mechanisms in case of wire breakage, ergonomic handles for better control, and comprehensive operator training programs. By adhering to best practices and manufacturer guidelines, concrete factory workers can minimize risks associated with using these advanced cutting tools.

Future Innovations in Diamond Wire Saw Technology for Concrete Applications

As technology continues to evolve, so does the potential of diamond wire saws. Future innovations promise even greater precision, efficiency, and sustainability. Research is underway to develop saws that are more environmentally friendly, consume less energy, and can handle even harder materials efficiently. As these advancements reach the market, they will further solidify the position of diamond wire saws as indispensable tools in concrete factories worldwide.

Diamond wire saws represent a significant leap forward in concrete cutting technology. Their combination of precision, efficiency, and cost-effectiveness makes them an invaluable asset for modern concrete factories looking to stay competitive in today’s fast-paced construction industry.

Request for Quotation

报错: 未找到这个表单