The Releated Products of Diamond Wire Saw Flywheel

Diamond Wire Saw Flywheel

Table of Contents

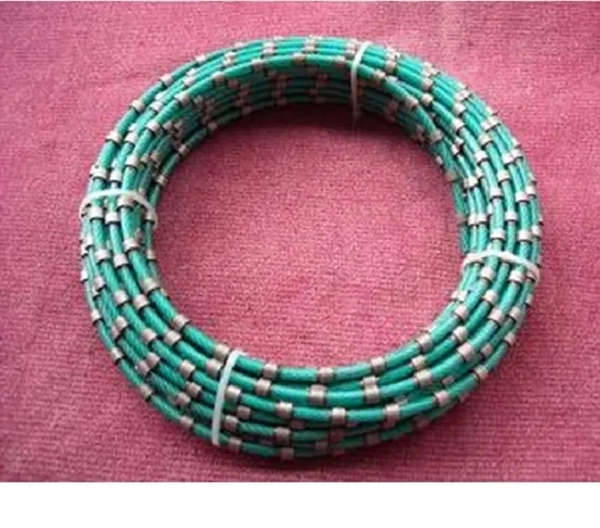

Understanding the Diamond Wire Saw Flywheel: A Mechanical Marvel

In the realm of industrial cutting, precision and efficiency are paramount. One such tool that has revolutionized the way hard materials are cut is the diamond wire saw flywheel. This innovative piece of equipment not only enhances accuracy but also boosts productivity in various applications. In this article, we delve into the intricacies of the diamond wire saw flywheel, exploring its design, benefits, and applications.

Diamond Wire Saw Flywheel Design: Enhancing Cutting Precision

The diamond wire saw flywheel is designed to provide a smooth, consistent motion during cutting operations. Its primary function is to store kinetic energy, which is then released to maintain the speed of the wire as it cuts through materials. By doing so, it ensures uniform pressure and reduces vibrations, leading to cleaner cuts and improved material handling. The wheel’s robust construction, typically made from high-strength steel or cast iron, allows it to withstand the rigorous demands of continuous operation.

Benefits of Using a Diamond Wire Saw Flywheel

Incorporating a diamond wire saw flywheel into industrial cutting processes offers several advantages. One key benefit is the reduction in energy consumption due to its ability to maintain cutting speeds even when encountering harder sections of material. Additionally, the flywheel’s role in stabilizing the cutting process results in less wear on the wire, extending its lifespan and reducing maintenance costs. These features collectively contribute to higher operational efficiency and lower overall expenses for manufacturers.

Applications of Diamond Wire Saw Flywheels

The versatility of diamond wire saw flywheels makes them suitable for a wide range of applications. They are particularly effective in industries requiring precise cuts of materials like stone, concrete, and metals. For instance, in the construction sector, they are used for cutting large slabs of marble or granite with unparalleled precision. Similarly, in metal fabrication shops, these tools can handle tough alloys with ease, ensuring clean edges and minimal material waste.

Maintenance Tips for Diamond Wire Saw Flywheels

To ensure optimal performance and longevity of your diamond wire saw flywheel, regular maintenance is essential. Start by keeping the wheel clean and free from debris that could interfere with its rotation. Lubrication of moving parts helps prevent rust and corrosion, while also reducing friction. Regular inspections should be conducted to check for any signs of wear or damage, addressing issues promptly to avoid more serious problems down the line.

How Does the Diamond Wire Saw Flywheel Improve Efficiency?

By maintaining a constant cutting speed, the diamond wire saw flywheel plays a crucial role in enhancing the efficiency of cutting processes. This stability is achieved through the flywheel’s capacity to store and release energy, ensuring that the wire maintains its momentum regardless of variations in material hardness. Consequently, operators can achieve faster cutting cycles without compromising on quality, leading to increased productivity levels across various industrial settings.

Conclusion: Embracing the Future with Diamond Wire Saw Flywheels

As technology continues to advance, the importance of adopting efficient and reliable machinery becomes increasingly evident. The diamond wire saw flywheel stands out as a testament to how innovation can transform traditional manufacturing methods. By offering unparalleled precision, durability, and cost-effectiveness, these devices are poised to shape the future of industrial cutting practices. Whether you’re involved in construction, mining, or metalworking, investing in a diamond wire saw flywheel can significantly elevate your operations’ standards.

Request for Quotation

报错: 未找到这个表单