The Releated Products of Diamond Wire Saw Cutting Concrete

Diamond Wire Saw Cutting Concrete

Diamond Wire Saw Cutting Concrete: Precision, Efficiency, and Versatility

In the realm of construction and demolition, diamond wire saw cutting concrete has emerged as a revolutionary technique, offering unparalleled precision and efficiency. This method involves using a thin, flexible wire embedded with industrial diamonds to cut through hard materials like reinforced concrete, stone, and masonry. The diamond segments on the wire act as cutting edges, allowing for clean, controlled cuts in structures of varying sizes and complexities.

Diamond Wire Saw: An Introduction to Cutting Concrete

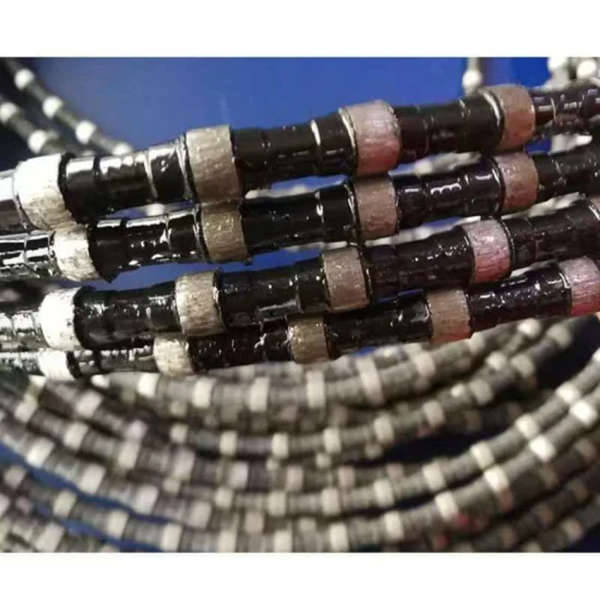

Diamond wire saws consist of a continuous loop of flexible wire studded with diamond segments. These saws are driven by one or more electric or hydraulic motors, which rotate the wire at high speeds. The key advantage of this technology lies in its ability to make precise cuts without generating significant vibration or noise pollution, making it ideal for use in sensitive environments such as hospitals or residential areas.

Applications of Diamond Wire in Cutting Concrete Structures

From bridge decks and foundations to large monolithic structures, diamond wire saws can tackle projects of all scales. They are particularly useful when traditional cutting methods are impractical or too disruptive. For instance, in scenarios where minimal disturbance to surrounding areas is required, or when cutting deep into thick concrete slabs, diamond wire sawing shines. It provides the capability to perform intricate cuts with remarkable accuracy, ensuring that structural integrity remains intact.

Advantages of Using Diamond Wire for Cutting Concrete

One of the primary benefits of diamond wire saw cutting concrete is its versatility. It can handle both straight and curved cuts, making it suitable for a wide range of applications. Additionally, because the process generates less dust compared to other cutting techniques, it creates a safer working environment. The reduced noise levels also contribute to a more pleasant workspace, especially in urban settings where noise ordinances must be considered.

Techniques for Efficient Diamond Wire Saw Cutting of Concrete

To achieve optimal results when cutting concrete with a diamond wire saw, several factors need to be considered. First, choosing the right type of diamond wire is crucial. Different wires are designed for varying hardnesses of material; selecting the appropriate one ensures maximum efficiency. Secondly, maintaining proper tension on the wire is essential for preventing breakage and achieving clean cuts. Lastly, controlling the speed at which the wire moves through the material helps prevent overheating and extends the life of the wire.

Maintenance and Care of Diamond Wire Used in Cutting Concrete

Proper maintenance of diamond wire saws is vital to their longevity and performance. After each use, the wire should be thoroughly cleaned to remove any debris or residue. Regular inspections for wear and tear are necessary to ensure safety and efficiency. Replacing worn-out segments promptly prevents damage to the machine and maintains cutting quality.

Future Trends in Diamond Wire Saw Cutting of Concrete

As technology advances, so does the sophistication of diamond wire saws. Innovations such as improved diamond segment designs and more efficient drive systems promise to further enhance the capabilities of these tools. Moreover, advancements in automation could lead to even greater precision and productivity in the future. As the industry continues to evolve, diamond wire saw cutting concrete will likely remain a cornerstone technique, driven by ongoing improvements and new applications.

By embracing the power and flexibility of diamond wire saw cutting concrete, professionals in the construction and demolition sectors can look forward to tackling complex projects with confidence, knowing they have a tool capable of delivering exceptional results every time.

Request for Quotation

报错: 未找到这个表单