The Releated Products of Diamond Wire Saw Cutter Machine

Diamond Wire Saw Cutter Machine

Diamond Wire Saw Cutter Machine: Precision Cutting Redefined

In the realm of industrial cutting, precision and efficiency are paramount. The diamond wire saw cutter machine has emerged as a game-changer, offering unparalleled accuracy and versatility. This article delves into the workings, benefits, and applications of these machines, highlighting why they are indispensable in modern manufacturing processes.

Efficiency of Diamond Wire Saw Cutter Machines

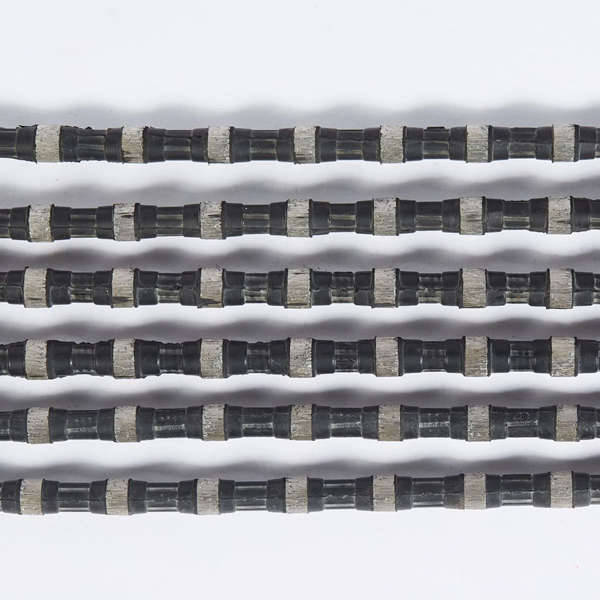

One of the most significant advantages of using a diamond wire saw cutter machine is its exceptional efficiency. These machines are designed to handle a wide range of materials, from soft stones like marble to extremely hard substances such as reinforced concrete. The continuous loop of diamond-impregnated wire allows for clean, precise cuts without the need for frequent blade changes, which is common in traditional cutting methods. This not only saves time but also reduces operational costs significantly.

Applications of Diamond Wire Saw Cutter Machines

The diamond wire saw cutter machine finds extensive use across various industries due to its ability to cut through different materials with ease. In construction, it is used for demolition and renovation projects where precision cutting of concrete structures is required. In the mining sector, these machines are employed for quarrying operations, especially when cutting large blocks of stone. Additionally, they play a crucial role in the semiconductor industry, where ultra-precise cuts are essential for fabricating electronic components.

Advantages of Using Diamond Wire Saw Cutter Machines

When considering the adoption of a diamond wire saw cutter machine, several key advantages stand out. Firstly, the technology behind these machines ensures minimal material loss during the cutting process, leading to higher yields and reduced waste. Secondly, the ability to make intricate cuts opens up new possibilities in design and fabrication, allowing manufacturers to produce more complex shapes and sizes. Lastly, because the cutting process generates less heat compared to traditional methods, there is a lower risk of thermal damage to the material being cut.

Maintenance and Safety Considerations for Diamond Wire Saw Cutter Machines

To ensure optimal performance and longevity of your diamond wire saw cutter machine, regular maintenance is essential. This includes checking the tension of the wire regularly, ensuring proper lubrication of moving parts, and replacing worn-out components promptly. Safety is another critical aspect; operators must wear appropriate personal protective equipment (PPE) and follow established safety protocols to prevent accidents. Proper training on how to operate the machine safely is also vital.

Future Innovations in Diamond Wire Saw Technology

As technology continues to advance, so does the development of diamond wire saw cutter machines. Current trends focus on enhancing automation levels, improving wire durability, and developing more environmentally friendly cutting solutions. For instance, some manufacturers are exploring the use of recycled materials in the production of diamond wires to reduce environmental impact. Furthermore, advancements in robotics are making it possible to automate many aspects of the cutting process, potentially revolutionizing how these machines are used in factories and construction sites.

The diamond wire saw cutter machine represents a significant leap forward in cutting technology, offering unmatched precision, versatility, and efficiency. As industries continue to evolve, these machines will undoubtedly play an increasingly important role in shaping the future of manufacturing and construction practices worldwide.

Request for Quotation

报错: 未找到这个表单