The Releated Products of Diamond Wire Saw Beads

Diamond Wire Saw Beads

Table of Contents

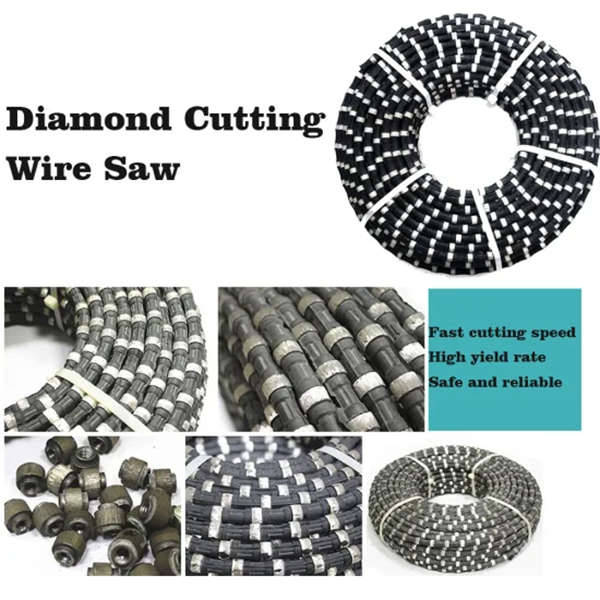

Understanding Diamond Wire Saw Beads: Precision in Cutting

Diamond wire saw beads are essential components of wire saws used in various industries for cutting through hard materials like stone, concrete, and metals. These beads are embedded with synthetic diamonds that provide the necessary hardness and durability required for cutting operations. The quality and design of these diamond wire saw beads significantly impact the performance and efficiency of the cutting process.

Diamond Wire Saw Beads Composition

The composition of diamond wire saw beads is critical to their effectiveness. Typically, they consist of a metal matrix, usually bronze or steel, which is impregnated with industrial-grade synthetic diamonds. The size, concentration, and distribution of these diamonds within the matrix play a crucial role in determining the cutting speed and the lifespan of the beads. Manufacturers often tailor the bead composition to suit specific applications, ensuring optimal performance across different materials and conditions.

Importance of Diamond Wire Saw Beads in Industrial Applications

In industrial settings, diamond wire saw beads are indispensable due to their ability to cut through extremely hard substances efficiently and precisely. They are particularly useful in the construction, mining, and manufacturing sectors where precision and reliability are paramount. By using diamond wire saw beads, operators can achieve clean cuts with minimal material loss, leading to cost savings and improved productivity.

Selection Criteria for Diamond Wire Saw Beads

Choosing the right diamond wire saw beads depends on several factors, including the type of material being cut, the desired cutting speed, and the expected lifetime of the beads. For softer materials, a higher concentration of smaller diamonds may be more effective, while harder materials might require larger diamonds with a lower concentration. Understanding these nuances helps in selecting the most appropriate beads for any given task, thereby enhancing operational efficiency and reducing downtime.

Maintenance and Care of Diamond Wire Saw Beads

Proper maintenance of diamond wire saw beads is vital to ensure their longevity and consistent performance. Regular inspection for wear and tear, cleaning, and proper storage when not in use can extend the life of the beads significantly. Additionally, adhering to manufacturer guidelines regarding operating parameters such as tension, speed, and cooling can prevent premature damage and enhance safety during operation.

Advancements in Diamond Wire Saw Beads Technology

Recent advancements in technology have led to improvements in the design and functionality of diamond wire saw beads. Innovations like laser welding techniques for attaching beads to the wire and the development of new diamond blends have resulted in stronger bonds and increased durability. These technological enhancements continue to push the boundaries of what is possible with wire saw cutting, making it faster, safer, and more efficient than ever before.

Future Prospects of Diamond Wire Saw Beads

Looking ahead, the future of diamond wire saw beads looks promising. As research into material science progresses, we can expect to see even more durable and versatile beads that can tackle increasingly challenging tasks. Moreover, the integration of smart technologies could allow for real-time monitoring and adjustment of cutting parameters, further optimizing the performance of wire saw systems. With ongoing developments, diamond wire saw beads will undoubtedly remain a cornerstone of industrial cutting processes well into the future.

Request for Quotation

报错: 未找到这个表单