The Releated Products of Diamond Wire Saw 3500

Diamond Wire Saw 3500

Table of Contents

Diamond Wire Saw 3500: Precision Cutting Redefined

In the world of construction and industrial cutting, precision and efficiency are paramount. The introduction of the Diamond Wire Saw 3500 has marked a significant advancement, offering unparalleled accuracy and speed in material cutting. This innovative tool stands out for its ability to handle complex projects with ease, making it a preferred choice among professionals.

Diamond Wire Saw 3500: Key Features

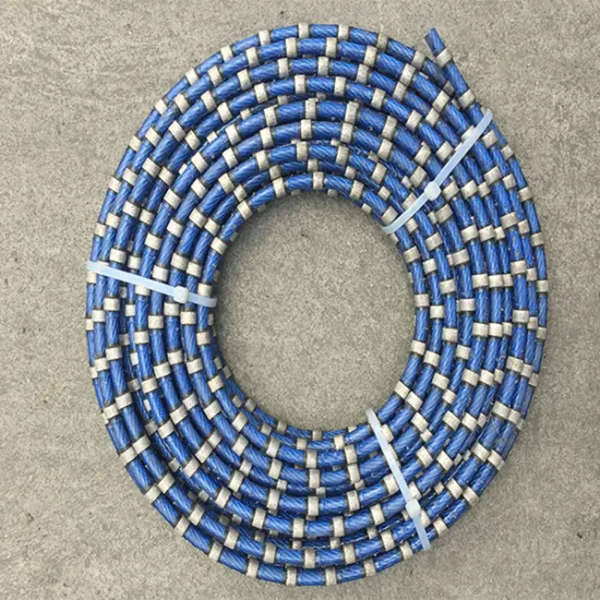

The Diamond Wire Saw 3500 is designed with advanced features that enhance its performance across various applications. Its robust motor provides the power needed for cutting through dense materials like reinforced concrete and stone. The saw’s wire, embedded with diamond segments, ensures clean cuts with minimal vibration, reducing wear and tear on the machine. Moreover, its adjustable speed settings allow operators to tailor the cutting process according to the material’s hardness and thickness, ensuring optimal results every time.

Applications of the Diamond Wire Saw 3500

From bridge demolition to mining operations, the versatility of the Diamond Wire Saw 3500 makes it indispensable in multiple industries. In construction, it is used for precise cutting of concrete structures, facilitating renovations and demolitions without damaging surrounding areas. For miners, this saw offers a safer alternative for extracting precious stones from quarries, minimizing waste and maximizing yield. Additionally, its use in the manufacturing sector for shaping and resizing materials has also proven highly effective, streamlining production processes.

Benefits of Using the Diamond Wire Saw 3500

One of the most significant advantages of the Diamond Wire Saw 3500 is its ability to cut continuously, leading to increased productivity on job sites. Unlike traditional saws that require frequent breaks to cool down, this model can operate for extended periods thanks to its efficient cooling system. Furthermore, the reduced noise levels compared to other cutting methods make it ideal for use in residential areas where minimizing disruption is crucial. Lastly, its compact design facilitates easy maneuverability, allowing users to work in confined spaces with ease.

Maintenance and Care of the Diamond Wire Saw 3500

To ensure longevity and peak performance of your Diamond Wire Saw 3500, regular maintenance is essential. Cleaning the unit after each use helps prevent buildup of debris that could interfere with operation. Lubricating moving parts periodically reduces friction and extends the life of the machine. Checking the tension of the wire regularly and replacing it when necessary prevents breakages during use, which can be costly and time-consuming. By following these simple guidelines, you can maintain the optimal condition of your saw, ensuring it remains a valuable asset for years to come.

How to Choose the Right Diamond Wire for Your Saw 3500

Selecting the appropriate wire for your Diamond Wire Saw 3500 depends largely on the material being cut and the desired outcome. Different wires are designed for specific applications; softer materials may require a finer wire, while harder substances necessitate a thicker, more durable option. Consulting with experts or referring to the manufacturer’s recommendations can guide you in making the best selection. Experimentation might also be required to find the perfect balance between speed and quality of cut.

Conclusion

The Diamond Wire Saw 3500 represents a leap forward in cutting technology, combining power, precision, and durability into one versatile tool. Whether you’re working on large-scale construction projects or intricate stonework, this saw delivers consistent performance that meets the demands of even the most challenging tasks. With proper care and the right accessories, the Diamond Wire Saw 3500 promises to be a reliable companion for all your cutting needs.

Request for Quotation

报错: 未找到这个表单