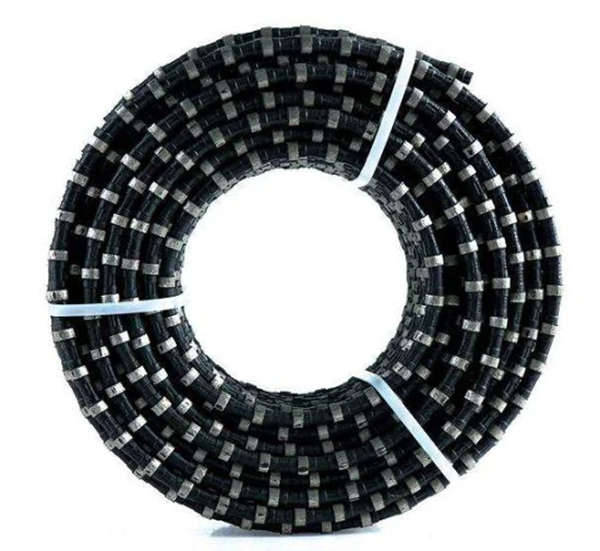

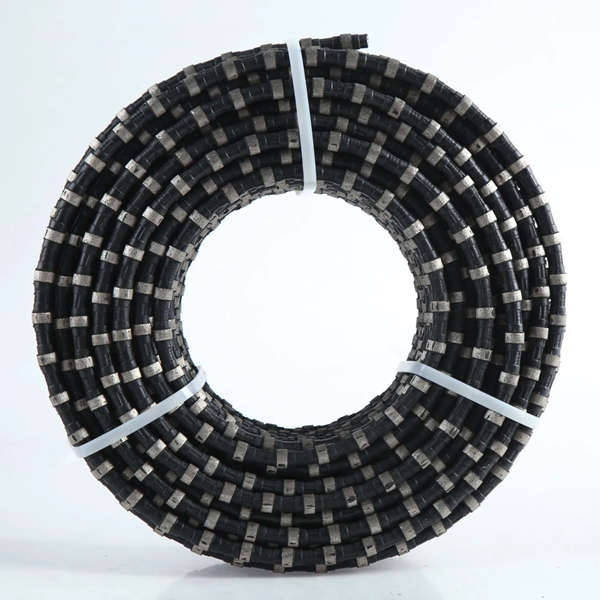

The Releated Products of Diamond Wire Jig Saw Machine Foam

Diamond Wire Jig Saw Machine Foam

Table of Contents

Diamond Wire Jig Saw Machine Foam: Precision Cutting for Diverse Applications

In the realm of precision cutting, the Diamond Wire Jig Saw Machine Foam has emerged as a versatile tool, revolutionizing industries from construction to manufacturing. This specialized foam technology is designed to enhance the performance of diamond wire saws, providing unparalleled accuracy and efficiency. Whether you’re working on intricate architectural projects or large-scale industrial applications, understanding the benefits and proper use of this innovative material can significantly improve your workflow.

Enhancing Precision with Diamond Wire Jig Saw Machine Foam

One of the key advantages of using Diamond Wire Jig Saw Machine Foam lies in its ability to increase cutting precision. The foam acts as a stabilizer, reducing vibrations during the cutting process. This leads to smoother cuts and a higher degree of accuracy, making it particularly useful for detailed work where every millimeter counts. Incorporating this foam into your setup can mean the difference between a good cut and a great one.

Durability and Longevity of Diamond Wire Jig Saw Machine Foam

When it comes to durability, Diamond Wire Jig Saw Machine Foam stands out among other materials used in similar applications. Its high resistance to wear and tear ensures that it maintains its effectiveness over extended periods of use. This longevity not only saves money by reducing the frequency of replacements but also minimizes downtime, allowing for continuous operation. For businesses looking to maximize productivity while maintaining quality, investing in durable foam can be a strategic decision.

Versatility of Diamond Wire Jig Saw Machine Foam Across Industries

The versatility of Diamond Wire Jig Saw Machine Foam extends beyond a single industry, making it valuable across various sectors. From cutting stone and concrete in construction to shaping metals in manufacturing plants, this foam adapts seamlessly to different materials and cutting requirements. Its adaptability means that regardless of the project’s specifics, there’s a configuration that will suit the job, ensuring optimal results every time.

Cost-Effectiveness of Using Diamond Wire Jig Saw Machine Foam

While initially considering the cost of Diamond Wire Jig Saw Machine Foam, some may hesitate due to upfront expenses. However, when factoring in the long-term savings associated with its use, the investment becomes clear. Reduced material waste, increased efficiency, and the foam’s durability all contribute to lower operational costs over time. Businesses that prioritize sustainability and cost management will find significant value in adopting this technology.

Proper Installation of Diamond Wire Jig Saw Machine Foam

To fully leverage the benefits of Diamond Wire Jig Saw Machine Foam, proper installation is crucial. Incorrect placement can diminish its effectiveness and potentially lead to premature wear. Manufacturers typically provide detailed instructions on how to integrate the foam into existing machinery. Following these guidelines meticulously ensures that the foam performs at its peak, delivering the precision and durability expected from such a specialized product.

Maintenance Tips for Diamond Wire Jig Saw Machine Foam

Like any piece of equipment, Diamond Wire Jig Saw Machine Foam requires regular maintenance to function optimally. Simple steps such as cleaning the foam after each use and storing it properly can extend its lifespan considerably. Regular inspections for signs of wear should also be conducted to catch any issues early on. By committing to a maintenance schedule, users can maintain the foam’s integrity and continue benefiting from its superior performance characteristics.

In conclusion, the Diamond Wire Jig Saw Machine Foam represents a significant advancement in cutting technology. Its ability to enhance precision, durability, and efficiency makes it an indispensable tool for professionals aiming to achieve top-quality results. Whether you’re just starting to explore its potential or are a seasoned user, understanding how to best utilize and care for this foam can unlock new levels of productivity and success in your projects.

Request for Quotation

报错: 未找到这个表单