The Releated Products of Diamond Wire Granite Saw

Diamond Wire Granite Saw

Table of Contents

Diamond Wire Granite Saw: Precision Cutting for Modern Applications

In the world of stone cutting and fabrication, precision and efficiency are paramount. The diamond wire granite saw has emerged as a revolutionary tool that meets these demands, offering unparalleled accuracy and speed. This article delves into the technology behind these saws, their applications, benefits, and why they are indispensable in today’s industry.

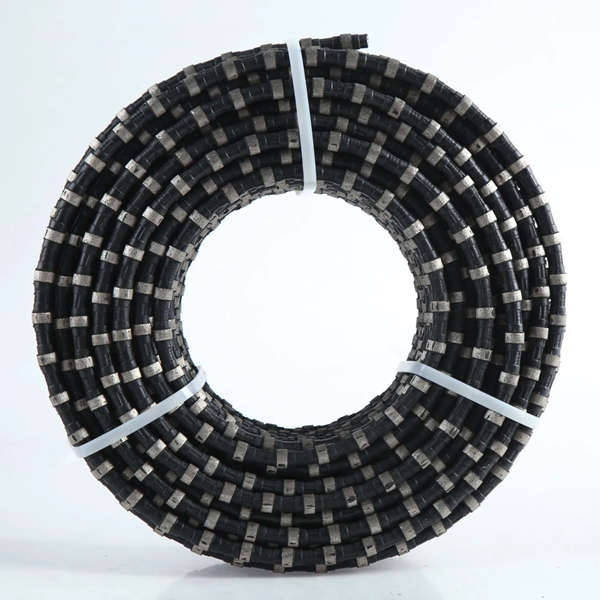

Diamond Wire Granite Saw Technology

The core of a diamond wire granite saw lies in its cutting medium—a thin wire embedded with industrial-grade diamonds. These diamonds act as cutting edges, slicing through granite with minimal material loss. Unlike traditional blade-based saws, the wire can be made incredibly long, allowing it to cut large blocks of stone efficiently. The continuous loop design ensures consistent cutting pressure, which is crucial for maintaining straight cuts over extended lengths.

Applications of the Diamond Wire Granite Saw

From quarries to workshops, the diamond wire granite saw finds application across various stages of granite processing. In quarries, it is used for primary cutting, separating massive blocks from the bedrock. Within manufacturing facilities, these saws play a critical role in shaping slabs into countertops, tiles, and other custom pieces. Its versatility makes it suitable for both rough and fine cuts, catering to diverse needs within the industry.

Benefits of Using a Diamond Wire Granite Saw

One significant advantage of the diamond wire granite saw is its ability to reduce waste. Since the wire makes a narrow cut, more material is retained compared to thicker blades. Additionally, water is used during the cutting process to cool the diamonds and suppress dust, creating a safer work environment. The saw’s ability to cut in any direction also enhances flexibility, making complex designs possible without compromising on quality or speed.

Maintenance and Care for Your Diamond Wire Granite Saw

To ensure optimal performance and longevity, regular maintenance of your diamond wire granite saw is essential. This includes inspecting the wire for wear and tear, replacing worn segments promptly, and cleaning the machine thoroughly after each use. Proper lubrication of moving parts and adherence to manufacturer guidelines on operating parameters (such as tension settings) will help maintain the saw’s cutting efficiency and extend its useful life.

Environmental Impact of Diamond Wire Granite Saws

While powerful and efficient, diamond wire granite saws also contribute positively to environmental sustainability efforts within the industry. By minimizing material waste, they help conserve natural resources. Furthermore, advancements in water recycling systems have reduced water consumption significantly, making these machines more eco-friendly than ever before. As environmental consciousness grows among consumers, adopting such technologies becomes not just beneficial but increasingly necessary for businesses looking to remain competitive.

Future Innovations in Diamond Wire Granite Saws

As technology continues to evolve, so too does the diamond wire granite saw. Research into new diamond compositions and wire materials promises even greater cutting speeds and durability. Integration with automation and robotics is streamlining production processes, enhancing accuracy while reducing labor costs. With ongoing improvements, these saws are poised to play an even more pivotal role in shaping the future of stone fabrication.

The diamond wire granite saw represents a significant leap forward in stone cutting technology, offering a potent combination of precision, efficiency, and sustainability. Whether you’re involved in quarry operations, countertop manufacturing, or architectural projects, investing in this advanced machinery can elevate your business capabilities and set you apart in today’s competitive landscape.

Request for Quotation

报错: 未找到这个表单