The Releated Products of Diamond Tip Wire Saw Granite

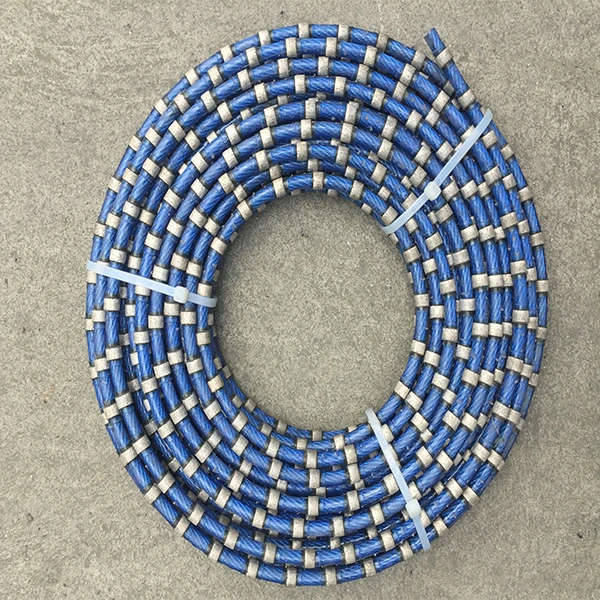

Diamond Tip Wire Saw Granite

Diamond Tip Wire Saw for Granite: Precision Cutting Redefined

In the world of stone cutting, precision and efficiency are paramount. This is especially true when working with granite—a material known for its beauty and durability. To meet these demands, diamond tip wire saws have become indispensable tools. Let’s explore how they work and why they’re essential for granite cutting projects.

Diamond Tip Wire Saw Granite: A Game-Changer in Construction

Diamond tip wire saws represent a technological leap forward in granite cutting. These machines use a thin, flexible wire embedded with diamond grains to slice through hard materials like granite. Unlike traditional blade saws, which can struggle with thicker slabs or uneven surfaces, diamond wire saws offer unparalleled versatility and control. They are particularly useful in quarries where large blocks of granite need to be extracted efficiently without compromising the structural integrity of the surrounding rock.

Benefits of Using Diamond Tip Wire Saws on Granite

When it comes to granite, traditional methods often fall short due to the hardness and density of this stone. Diamond tip wire saws, however, excel in several key areas:

– Precision: The fine wire allows for precise cuts, reducing waste and improving overall yield.

– Speed: Despite being gentle on the material, these saws can cut faster than many other options available.

– Safety: By minimizing vibration and noise, they create safer working conditions compared to conventional cutting techniques.

– Flexibility: Ideal for both straight and curved cuts, making them suitable for intricate designs and complex projects.

How Diamond Tip Wire Saws Cut Granite Efficiently

The effectiveness of diamond tip wire saws lies in their design. The wire, studded with industrial-grade diamonds, acts as an abrasive tool that grinds away at the granite surface. As the wire moves continuously, it gradually removes layers of stone until the desired shape or size is achieved. This process is water-cooled to prevent overheating and ensure the longevity of the diamonds embedded in the wire.

Choosing the Right Diamond Tip Wire Saw for Granite Projects

Selecting the appropriate diamond tip wire saw depends on several factors including the thickness of the granite, the complexity of the cut required, and the scale of your project. For small-scale operations or detailed work, handheld versions provide excellent maneuverability. Larger quarry operations might require more robust machinery capable of handling massive slabs efficiently. Consulting with a professional who understands your specific needs can help guide you towards the best option.

Maintenance Tips for Diamond Tip Wire Saws Used on Granite

To keep your diamond tip wire saw operating at peak performance, regular maintenance is crucial. This includes inspecting the wire for wear and tear, ensuring proper alignment of the guide wheels, and maintaining adequate water flow during operation. Regular cleaning to remove debris and grit from the machine will also extend its lifespan significantly.

Applications of Diamond Tip Wire Saws in Granite Industries

From architectural marvels to everyday countertops, granite’s popularity shows no signs of waning. Diamond tip wire saws play a pivotal role in bringing these visions to life by enabling precise, efficient cuts that preserve the natural beauty of the stone. Whether you’re a sculptor looking to carve intricate designs or a contractor tasked with installing granite floors across a sprawling commercial space, these tools deliver unmatched results every time.

By embracing the power of diamond tip wire saw technology, professionals in the granite industry can achieve new heights of creativity while ensuring productivity and profitability.

Request for Quotation

报错: 未找到这个表单