The Releated Products of Diamond Spring Wire Saw

Diamond Spring Wire Saw

Table of Contents

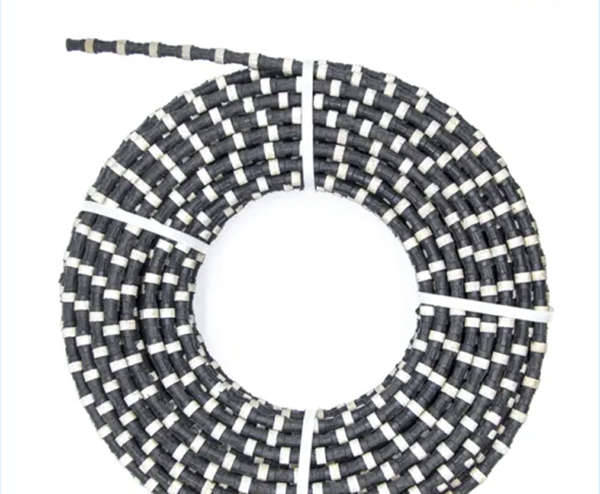

Diamond Spring Wire Saw: Precision Cutting Redefined

In the world of industrial cutting, precision and efficiency are paramount. One tool that has revolutionized the industry is the Diamond Spring Wire Saw. This advanced cutting technology combines the durability of diamond with the flexibility of wire, making it ideal for a wide range of applications, from quarrying to construction and even in the manufacturing sector.

Efficiency of Diamond Spring Wire Saws

The Diamond Spring Wire Saw offers unparalleled efficiency when compared to traditional cutting methods. Its design incorporates a flexible steel cable embedded with diamond particles, which allows for precise cuts through hard materials like stone, concrete, and reinforced concrete. The spring mechanism within the wire enhances its cutting performance by maintaining constant tension, ensuring smoother cuts and reducing the risk of breakage during operation.

Applications of Diamond Spring Wire Saws

From the extraction of large blocks of marble or granite in quarries to the demolition of concrete structures, the Diamond Spring Wire Saw proves its versatility across various industries. In construction, it enables clean, controlled cuts without causing damage to surrounding areas. For stonemasons and sculptors, this tool provides the ability to create intricate designs with minimal effort, enhancing both productivity and artistic expression.

Benefits of Using Diamond Spring Wire Saws

One of the key benefits of using a Diamond Spring Wire Saw is its ability to cut with minimal vibration, which reduces noise pollution and improves safety on job sites. Additionally, because the wire can be guided around obstacles, it offers greater maneuverability and access to hard-to-reach areas. These features not only increase productivity but also extend the lifespan of the saw by minimizing wear and tear.

Maintenance of Diamond Spring Wire Saws

Proper maintenance is crucial for extending the life of your Diamond Spring Wire Saw. Regular cleaning to remove debris and lubrication of moving parts help maintain optimal performance. It’s also important to inspect the wire regularly for signs of wear or damage. Replacing worn segments promptly ensures continued efficiency and safety during operations.

Advantages Over Traditional Cutting Methods

Compared to traditional saws, the Diamond Spring Wire Saw offers several advantages. Its ability to make thin kerf cuts means less material is removed during the cutting process, resulting in higher yields. Furthermore, the lack of a blade means there’s no need for frequent sharpening, saving time and reducing downtime. Lastly, the ability to cut underwater makes it particularly useful in wet environments where other tools might struggle.

Future Innovations in Diamond Spring Wire Saws

As technology advances, so too does the potential of the Diamond Spring Wire Saw. Research into new diamond formulations and more durable wire compositions promises even greater cutting efficiency and longevity. Moreover, developments in automation could lead to the integration of these saws into robotic systems, further enhancing their capabilities and expanding their use in various sectors.

In conclusion, the Diamond Spring Wire Saw represents a significant leap forward in cutting technology. Its combination of precision, efficiency, and versatility makes it an indispensable tool for professionals seeking reliable solutions to challenging cutting tasks. As innovations continue, the future looks bright for this remarkable piece of machinery.

Request for Quotation

报错: 未找到这个表单