The Releated Products of Diamond Saw Rope

Diamond Saw Rope

Table of Contents

Diamond Saw Rope: Precision Cutting for Tough Materials

Diamond saw rope, a specialized tool designed for cutting through hard materials like concrete, stone, and reinforced concrete, has revolutionized the construction industry. Its unique design allows for precise cuts with minimal material loss, making it indispensable in various applications. Whether you’re involved in bridge demolition, cutting large blocks of marble, or performing intricate stone work, understanding the capabilities and benefits of diamond saw rope can significantly enhance your project outcomes.

Diamond Saw Rope: An Overview

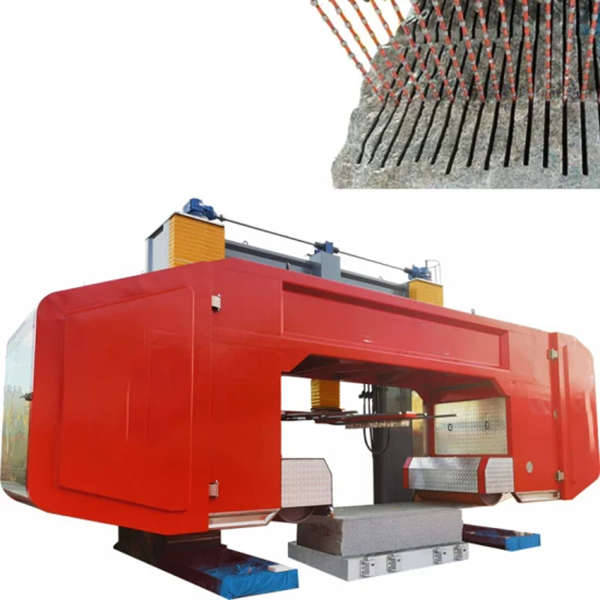

Diamond saw rope, also known as diamond wire saw, consists of a flexible steel cable embedded with diamond segments along its length. These segments act as cutting edges, enabling the rope to slice through dense materials efficiently. The diamond particles are typically bonded to metal segments using a process called electroplating or sintering, which ensures they remain securely attached during operation.

Benefits of Using Diamond Saw Rope

One of the key advantages of diamond saw rope is its ability to provide clean, accurate cuts without causing thermal damage to the surrounding material. This precision makes it ideal for applications where maintaining the integrity of nearby structures is crucial. Additionally, because the rope can be threaded through pre-drilled holes, it offers unparalleled flexibility in terms of cut direction and depth.

Applications of Diamond Saw Rope

From architectural restoration projects requiring delicate work to industrial settings needing rapid, efficient material removal, diamond saw rope finds application across a broad spectrum. In construction, it’s used for cutting slabs, beams, and columns, while in mining operations, it helps in extracting valuable minerals from rock formations. The versatility of diamond saw rope extends to its use in creating decorative stone elements, demonstrating its suitability for both functional and aesthetic purposes.

Maintenance and Care of Diamond Saw Rope

To ensure optimal performance and longevity, proper maintenance of diamond saw rope is essential. Regular inspection for wear and tear, cleaning after each use to remove debris, and storing the rope in a dry place away from corrosive substances are fundamental steps. Proper lubrication can also help reduce friction during cutting, extending the life of the rope and enhancing its cutting efficiency.

Choosing the Right Diamond Saw Rope

Selecting the appropriate diamond saw rope depends on several factors including the hardness of the material being cut, the desired speed of cutting, and the specific requirements of the job. For softer materials, ropes with larger diamond segments may be more effective, whereas harder materials might require finer, more densely packed segments. Consulting with a professional or manufacturer can provide guidance tailored to your specific needs.

Future Innovations in Diamond Saw Rope Technology

As technology advances, so too does the development of diamond saw rope. New materials and manufacturing techniques are continuously being explored to improve durability, cutting speed, and overall efficiency. Research into more sustainable production methods and eco-friendly diamond alternatives signals a promising future for this versatile cutting tool, ensuring its relevance in an increasingly environmentally conscious world.

Diamond saw rope continues to play a critical role in modern construction and manufacturing processes, offering a combination of precision, flexibility, and power that few other tools can match. As its technology evolves, we can expect to see even more innovative applications and improvements in performance, making it a staple in the toolbox of professionals for years to come.

Request for Quotation

报错: 未找到这个表单