The Releated Products of Diamond Powder For Saw Wire

Diamond Powder For Saw Wire

Table of Contents

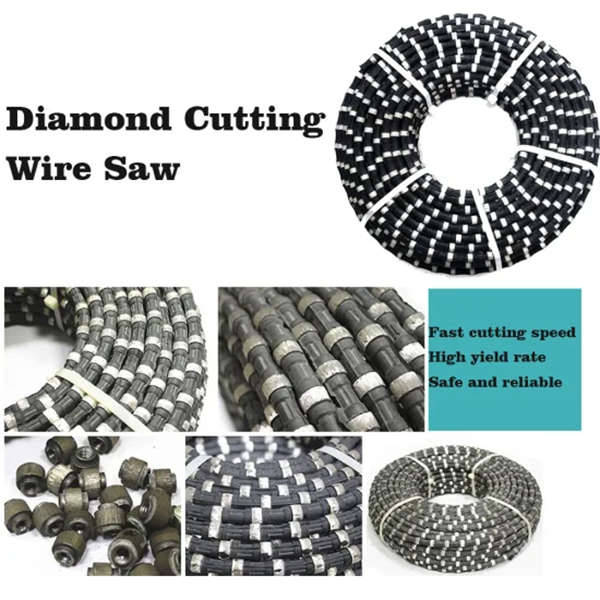

Diamond Powder for Saw Wire: Precision Cutting Redefined

Diamond powder for saw wire has revolutionized the precision cutting industry, offering unparalleled efficiency and durability. This fine abrasive material is meticulously engineered to enhance the performance of wire saws used in various applications, from semiconductor manufacturing to stone processing. By understanding the properties, applications, and benefits of diamond powder for saw wire, manufacturers can achieve superior results while reducing operational costs.

The Composition and Properties of Diamond Powder for Saw Wire

Diamond powder for saw wire is typically composed of synthetic diamonds that have been crushed and graded into specific sizes. These particles are then mixed with metal bonds and attached to a thin metal wire, creating a highly effective cutting tool. The hardness and thermal conductivity of diamond make it ideal for slicing through hard materials such as silicon wafers or granite slabs. Additionally, the particle size and distribution play a crucial role in determining the cutting speed and surface finish quality.

Applications of Diamond Powder for Saw Wire in Industry

The versatility of diamond powder for saw wire makes it indispensable across multiple industries where precision cutting is essential. In the semiconductor sector, it enables the accurate slicing of silicon ingots into thin wafers used in electronics. For construction and stonemasonry, these wires cut through marble, granite, and other stones with minimal effort. Moreover, advancements in technology have expanded its use into niche areas like solar panel production and medical device manufacturing, further highlighting its adaptability.

Advantages of Using Diamond Powder for Saw Wire

When compared to traditional cutting methods, diamond powder for saw wire offers several advantages that contribute significantly to productivity gains and cost savings. Firstly, its ability to maintain sharpness over prolonged periods reduces the need for frequent replacements or resharpening. Secondly, the precision offered by these tools minimizes material waste during the cutting process, which is particularly beneficial when working with expensive raw materials. Lastly, the smoother cuts produced help in achieving better final product quality without requiring extensive post-processing.

Factors Influencing the Selection of Diamond Powder for Saw Wire

Choosing the right type of diamond powder for saw wire depends on several factors including the hardness of the material being cut, desired cutting speed, and required surface finish quality. Particle size is one critical consideration; finer powders provide smoother finishes but may reduce cutting speed. Conversely, coarser powders increase cutting efficiency at the expense of surface quality. Manufacturers must also evaluate bond types, as they affect how securely the diamonds adhere to the wire and influence overall tool life.

Maintenance and Care of Diamond Powder for Saw Wire

To ensure optimal performance and longevity of diamond powder for saw wire, proper maintenance practices are essential. Regular cleaning helps remove debris that can accumulate between the diamond particles and impede cutting efficiency. Additionally, storing these tools in a dry environment prevents corrosion and maintains their integrity. Periodic inspection for signs of wear or damage allows for timely replacement, preventing potential downtime or reduced productivity.

Future Innovations in Diamond Powder for Saw Wire Technology

As research continues into enhancing the capabilities of diamond powder for saw wire, we can expect further improvements in both performance and sustainability. Emerging trends include the development of eco-friendly bonding agents and the exploration of new diamond synthesis techniques aimed at producing even harder, more durable particles. These innovations promise not only to push the boundaries of what’s possible with current applications but also to open up entirely new markets for this versatile cutting solution.

By embracing the latest advancements in diamond powder for saw wire technology, industries stand to gain significant competitive advantages. From enhanced precision and efficiency to reduced environmental impact, the future looks bright for those who invest in this cutting-edge tool.

Request for Quotation

报错: 未找到这个表单