The Releated Products of Diamond Multi Wire Saw

Diamond Multi Wire Saw

Table of Contents

Diamond Multi Wire Saw: Precision and Efficiency in Modern Cutting Technology

In the realm of industrial cutting, precision and efficiency are paramount. One technology that has revolutionized the way we cut hard materials such as stone and silicon is the diamond multi wire saw. This innovative tool not only enhances productivity but also reduces waste, making it a preferred choice for manufacturers worldwide.

Benefits of Using a Diamond Multi Wire Saw

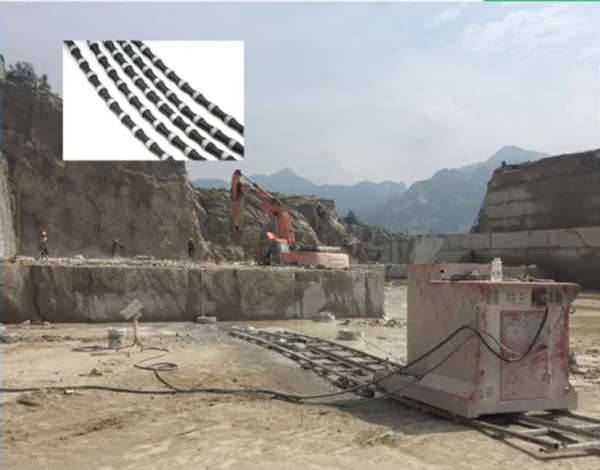

The diamond multi wire saw stands out due to its ability to perform intricate cuts with unparalleled accuracy. Its design incorporates multiple thin wires coated with diamond particles, allowing for simultaneous slicing of multiple pieces from a block or slab. This capability significantly speeds up production processes while maintaining high levels of precision.

Moreover, the use of diamond multi wire saws leads to minimal material loss during cutting, which translates into substantial cost savings over time. The reduced friction generated by these fine wires also results in cooler operations, further extending the life of both the saw and the material being cut.

How Does a Diamond Multi Wire Saw Work?

Understanding how a diamond multi wire saw operates provides insight into its effectiveness. Essentially, a series of parallel steel wires, typically made from stainless steel and embedded with synthetic diamonds, are stretched between two or more spools. These wires move continuously at high speeds, cutting through materials as they are fed into the machine.

The key to this process lies in the diamond particles, which act as the cutting agents. As the wires pass through the material, these abrasive particles grind away at the surface, creating clean, precise cuts. The continuous motion ensures uniformity across all cuts, regardless of the hardness of the material.

Applications of Diamond Multi Wire Saws

From construction to semiconductor manufacturing, the applications of diamond multi wire saws are vast and varied. In the construction industry, these saws are used extensively for cutting marble, granite, and other natural stones. Their ability to make precise cuts without causing damage to surrounding areas makes them ideal for creating tiles, countertops, and architectural elements.

In the semiconductor industry, diamond multi wire saws play a crucial role in wafer dicing. The precision required when separating silicon wafers into individual chips demands tools capable of producing extremely fine and accurate cuts. Here, the diamond multi wire saw excels, contributing to higher yields and better product quality.

Advantages Over Traditional Cutting Methods

When compared to traditional methods like single blade saws or gang saws, diamond multi wire saws offer several advantages. They consume less energy, produce less noise, and generate minimal dust, making them environmentally friendly and safer to operate.

Additionally, because they can cut multiple slices simultaneously, diamond multi wire saws drastically reduce processing times. This efficiency is particularly beneficial in industries where large volumes of material need to be processed quickly and accurately.

Maintenance and Care of Diamond Multi Wire Saws

To ensure optimal performance and longevity, regular maintenance of diamond multi wire saws is essential. This includes cleaning the machine thoroughly after each use to remove any debris or residue that might accumulate on the wires or spools. Lubrication of moving parts is also important to prevent wear and tear.

Periodic inspection of the wires for signs of wear is crucial. Damaged or worn-out wires should be replaced promptly to avoid compromising the quality of cuts and potentially damaging the saw itself. Proper storage in a dry environment helps protect the machinery from corrosion and extends its usable life.

Future Innovations in Diamond Multi Wire Saw Technology

As technology continues to advance, so too does the potential of diamond multi wire saws. Research is currently underway to develop even finer wires and more durable diamond coatings, aiming to achieve even greater precision and efficiency.

Moreover, efforts are being made to integrate smart technologies into these machines, enabling real-time monitoring and adjustments based on material characteristics. Such innovations promise to push the boundaries of what’s possible with diamond multi wire saws, ensuring their continued relevance in an ever-evolving industrial landscape.

The diamond multi wire saw represents a significant leap forward in cutting technology, offering unmatched precision, efficiency, and versatility. As industries continue to seek ways to improve productivity and sustainability, the role of these advanced cutting tools will only become more prominent.

Request for Quotation

报错: 未找到这个表单