The Releated Products of Diamond Jigsaw Blade For Granite

Diamond Jigsaw Blade For Granite

Table of Contents

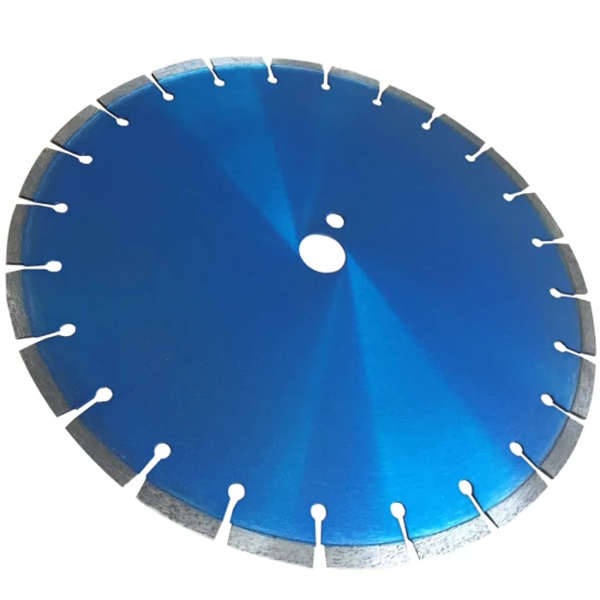

Diamond Jigsaw Blade for Granite: Precision Cutting Simplified

In the world of construction and home improvement, precision and durability are paramount. When it comes to cutting granite—a material known for its hardness and beauty—having the right tool can make all the difference. Enter the diamond jigsaw blade for granite, a specialized tool designed to tackle one of nature’s toughest materials. This article explores the features, benefits, and applications of these blades, helping you achieve clean, precise cuts every time.

The Superiority of Diamond Blades for Granite

Diamond blades stand out among other cutting tools due to their composition. These blades are embedded with synthetic diamonds, which are incredibly hard and able to cut through dense materials like granite with relative ease. The diamond jigsaw blade for granite is specifically engineered to handle the rigors of cutting this stone, ensuring smoother, more controlled cuts compared to traditional metal blades.

Choosing the Right Diamond Jigsaw Blade for Granite

Not all diamond blades are created equal, and selecting the appropriate one depends on several factors including the thickness of the granite, the type of cut required (straight or curved), and the power of your jigsaw. High-quality blades will have a segment height that matches the task at hand, ensuring optimal performance and longevity. Additionally, consider the blade’s diameter; larger diameters generally allow for deeper cuts, making them ideal for thicker slabs of granite.

Enhancing Performance with Proper Technique

Using a diamond jigsaw blade for granite requires some skill and practice. To get the best results, always ensure that the blade is sharp and correctly mounted on your jigsaw. Start by marking the cut lines clearly on the granite surface. Apply steady pressure while guiding the jigsaw along the marked lines, allowing the blade to do most of the work. Cooling the blade during operation, either by using water or air, helps maintain its integrity and prolongs its life.

Maintenance Tips for Your Diamond Jigsaw Blade for Granite

Like any tool, diamond jigsaw blades require proper care to perform optimally over time. After each use, clean the blade thoroughly to remove any debris or residue. Store it in a dry place away from moisture and direct sunlight, which can degrade the blade’s quality. Periodic inspections for wear and tear are also recommended; replace the blade if you notice significant damage or a decrease in cutting efficiency.

Safety Considerations When Using Diamond Jigsaw Blades for Granite

Safety should always come first when working with power tools and abrasive materials such as granite. Wear protective gear, including goggles, gloves, and a dust mask, to shield yourself from flying particles and dust. Make sure your workspace is well-lit and free of clutter. Lastly, follow the manufacturer’s instructions regarding the maximum cutting depth and speed settings for your specific diamond jigsaw blade model.

Innovative Uses of Diamond Jigsaw Blades for Granite

While primarily used for cutting granite countertops and tiles, these versatile blades can be applied to other hard materials like marble, quartz, and concrete. Craftsmen often utilize them for creating intricate designs or custom pieces where precision is key. The ability to achieve both straight and curved cuts makes diamond jigsaw blades a valuable addition to any workshop looking to expand its capabilities beyond standard granite fabrication.

By investing in a high-quality diamond jigsaw blade for granite and mastering its use, professionals and DIY enthusiasts alike can elevate their projects to new heights. Whether renovating a kitchen or crafting bespoke stonework, this tool promises unparalleled performance and reliability.

Request for Quotation

报错: 未找到这个表单