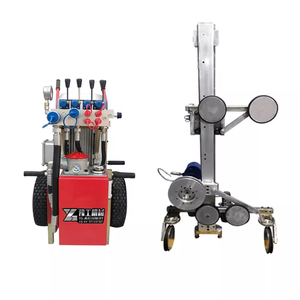

The Releated Products of Diamond Hole Cutter

Diamond Hole Cutter

Understanding Diamond Hole Cutters: Precision Cutting for Hard Materials

In the world of industrial cutting tools, diamond hole cutters stand out as essential instruments for precision work on hard materials. These specialized tools are designed to make clean, accurate cuts in surfaces such as ceramic tiles, marble, granite, and concrete. With their durable construction and efficient performance, they offer a level of reliability that other cutting methods often cannot match.

Diamond Hole Cutter Design and Construction

Diamond hole cutters derive their name and effectiveness from the diamonds embedded in their outer rim. These diamonds act as abrasives, grinding away at the material being cut. The core of a diamond hole cutter is typically made from steel or tungsten carbide, providing strength and durability while the diamonds do the cutting work. Different designs can be optimized for various applications, ensuring there’s a cutter suitable for almost any job requiring precision and strength.

Applications of Diamond Hole Cutters

From construction sites to DIY projects, diamond hole cutters find extensive use across multiple industries. They are particularly useful in plumbing and electrical installations where holes need to be drilled through walls or floors without damaging the surrounding area. Additionally, in the manufacturing sector, these cutters help achieve precise dimensions when working with materials like glass or stone, which are otherwise challenging to process accurately.

Benefits of Using Diamond Hole Cutters

One of the primary advantages of using diamond hole cutters is their ability to maintain sharpness over long periods, even when cutting through extremely hard materials. This longevity translates into cost savings as replacements are needed less frequently compared to other types of cutters. Moreover, because they produce smoother edges with less chipping, they often eliminate the need for secondary finishing processes, further enhancing efficiency.

Maintenance and Care of Diamond Hole Cutters

To ensure optimal performance and extend the lifespan of your diamond hole cutter, proper maintenance is crucial. After each use, rinse the cutter thoroughly under running water to remove any debris. Avoid exposing it to extreme temperatures, as this can damage the bond between the diamonds and the metal matrix. Regular inspection for wear or damage will also help you identify when it’s time to replace the tool, preventing potential accidents or subpar results during critical operations.

Choosing the Right Diamond Hole Cutter

Selecting the appropriate diamond hole cutter depends on several factors, including the material being cut, the size of the hole required, and the frequency of use. For occasional household tasks, a general-purpose cutter might suffice. However, professionals engaged in frequent cutting activities will benefit more from high-grade models designed for durability and consistent performance. Always consider the specific requirements of your project to make the most informed choice.

Advancements in Diamond Hole Cutter Technology

As technology continues to evolve, so too does the design and functionality of diamond hole cutters. Newer models incorporate advanced features like improved bonding techniques between the diamond segments and the core, resulting in better heat dissipation and longer tool life. Some manufacturers are also experimenting with innovative diamond configurations that promise enhanced cutting speed without compromising on edge quality.

By investing in quality diamond hole cutters and understanding how to best utilize them, professionals and enthusiasts alike can achieve superior results in their cutting projects. Whether tackling tough industrial jobs or managing home improvements, these versatile tools remain indispensable for achieving precision and efficiency in cutting hard materials.

Request for Quotation

报错: 未找到这个表单