The Releated Products of Diamond Cutting Wire Saw

Diamond Cutting Wire Saw

Table of Contents

Diamond Cutting Wire Saw: Precision and Power in Modern Masonry

In the dynamic landscape of construction and mining, precision and efficiency are paramount. One tool that has revolutionized these industries is the diamond cutting wire saw. This advanced technology combines the strength of diamonds with the flexibility of wire, allowing for precise cuts through even the hardest materials. This article explores the intricacies, applications, and benefits of diamond cutting wire saws, highlighting why they have become indispensable in various sectors.

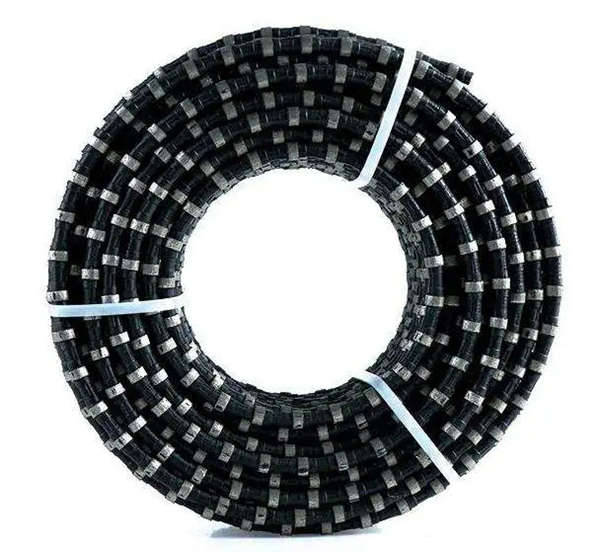

Diamond Cutting Wire Saw Technology

Understanding the core technology behind diamond cutting wire saws is essential to appreciating their capabilities. These saws consist of a thin, flexible wire embedded with synthetic diamond grains. The wire is strung between two or more pulleys and oscillated at high speeds, enabling it to cut through dense materials like reinforced concrete, marble, granite, and even steel. The key advantage lies in the wire’s ability to make intricate cuts without causing significant damage to surrounding areas.

Applications of Diamond Cutting Wire Saws

The versatility of diamond cutting wire saws makes them suitable for a wide range of applications. In construction, they are used for demolition projects where precision is critical, such as cutting structural beams or removing sections of buildings. Mining operations benefit from their use in extracting gemstones and precious metals from rock formations. Additionally, they play a crucial role in the fabrication of stone countertops and monuments, ensuring clean, accurate edges.

Benefits of Using Diamond Cutting Wire Saws

Several key benefits underscore the popularity of diamond cutting wire saws among professionals. First, their precision minimizes material waste, reducing costs associated with rework or disposal. Second, the reduced noise and vibration levels compared to traditional saws create a safer working environment. Lastly, the ability to make curved cuts opens up new possibilities in design and architecture, pushing the boundaries of what can be achieved aesthetically.

Maintenance and Care for Diamond Cutting Wire Saws

To ensure optimal performance and longevity, proper maintenance of diamond cutting wire saws is crucial. Regular inspection for wear and tear, along with cleaning the wire to remove debris, helps maintain cutting efficiency. Lubrication of moving parts reduces friction and extends the life of the equipment. It’s also important to store the saw properly when not in use, protecting it from moisture and extreme temperatures that could degrade its components over time.

Innovations in Diamond Cutting Wire Saw Design

Advancements in technology continue to enhance the capabilities of diamond cutting wire saws. Newer models feature improved diamond coatings that increase durability and cutting speed. Automation in some systems allows for remote operation, enhancing safety and productivity on job sites. Research into alternative materials for the wire itself may lead to even stronger, more resilient tools capable of tackling increasingly challenging tasks.

Future Prospects for Diamond Cutting Wire Saws

As industries evolve, so too will the demand for more sophisticated diamond cutting wire saws. Future developments might focus on integrating artificial intelligence to optimize cutting patterns and reduce human error. There’s also potential for miniaturization, making these tools accessible for more specialized applications. Regardless of how technology progresses, one thing remains certain: diamond cutting wire saws will remain a vital component in the toolkit of professionals across multiple fields.

Request for Quotation

报错: 未找到这个表单