The Releated Products of Diamond Coated Saw Wire 010

Diamond Coated Saw Wire 010

Table of Contents

Diamond Coated Saw Wire 010: Precision Cutting Redefined

In the realm of precision cutting, advancements in technology have revolutionized the way we approach material processing. One such innovation that has gained significant traction is the Diamond Coated Saw Wire 010. This specialized tool offers unparalleled accuracy and efficiency, making it indispensable across various industries. This article delves into the unique features, applications, and benefits of using diamond coated saw wire, specifically focusing on the 010 variant.

Diamond Coated Saw Wire 010: Enhanced Durability

Durability is a critical factor when selecting tools for industrial applications. The Diamond Coated Saw Wire 010 stands out due to its robust construction. The wire is meticulously coated with synthetic diamonds, providing a hard-wearing surface that can withstand the rigors of continuous use. These diamonds are not only durable but also maintain their sharpness over extended periods, reducing the need for frequent replacements or maintenance.

Efficiency in Cutting Hard Materials with Diamond Coated Saw Wire 010

One of the most notable advantages of the Diamond Coated Saw Wire 010 lies in its ability to cut through extremely hard materials with ease. Whether it’s silicon carbide, sapphire, or other tough substrates, this tool delivers clean, precise cuts without compromising on speed. The diamond coating ensures minimal wear, allowing for consistent performance even during prolonged operations.

Improved Precision with Diamond Coated Saw Wire 010

Precision is paramount in many manufacturing processes, particularly in semiconductor wafering and solar panel fabrication. The Diamond Coated Saw Wire 010 excels here by offering exceptional control and accuracy. Its fine diameter combined with the diamond coating allows for narrow kerf cuts, which translates into less material waste and higher yields. This makes it an ideal choice for applications where tight tolerances are required.

Sustainability and Cost-Effectiveness of Diamond Coated Saw Wire 010

Beyond its technical capabilities, the Diamond Coated Saw Wire 010 also contributes positively to sustainability efforts within industries. By reducing material wastage through narrower cuts, it helps lower overall production costs. Additionally, the durability of the diamond coating means fewer replacements are needed, further enhancing cost-effectiveness. This sustainable approach aligns well with the growing emphasis on eco-friendly manufacturing practices.

Maintenance and Longevity of Diamond Coated Saw Wire 010

To ensure the longevity of Diamond Coated Saw Wire 010, proper maintenance is essential. Regular cleaning and inspection can help identify any signs of wear early on, allowing for timely adjustments or replacements. Manufacturers often provide specific guidelines on how to best care for these wires, ensuring they remain in optimal condition throughout their service life. This proactive approach not only extends the life of the tool but also maintains its cutting efficiency.

Applications of Diamond Coated Saw Wire 010

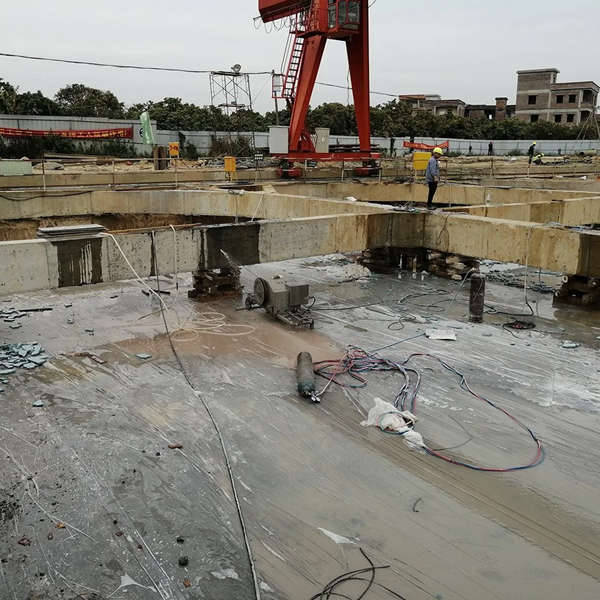

The versatility of Diamond Coated Saw Wire 010 makes it suitable for a wide range of applications. From electronics and photovoltaics to aerospace engineering, this tool plays a crucial role in many advanced manufacturing processes. Its ability to handle both delicate and robust materials with equal proficiency makes it a go-to solution for precision cutting tasks across diverse sectors.

By investing in Diamond Coated Saw Wire 010, businesses can achieve higher productivity levels while maintaining the highest standards of quality and precision. As technology continues to evolve, tools like these will undoubtedly play an increasingly important role in shaping the future of manufacturing and material processing.

Request for Quotation

报错: 未找到这个表单