The Releated Products of Diamond Cable Wire Saw

Diamond Cable Wire Saw

Table of Contents

Diamond Cable Wire Saw: Precision Cutting Redefined

In the realm of advanced cutting technologies, diamond cable wire saws have emerged as a game-changer, offering unparalleled precision and efficiency. These saws are particularly beneficial for applications where traditional cutting methods fall short. From construction to mining, understanding the nuances of diamond cable wire saw technology can unlock new possibilities in material processing.

Efficiency of Diamond Cable Wire Saws

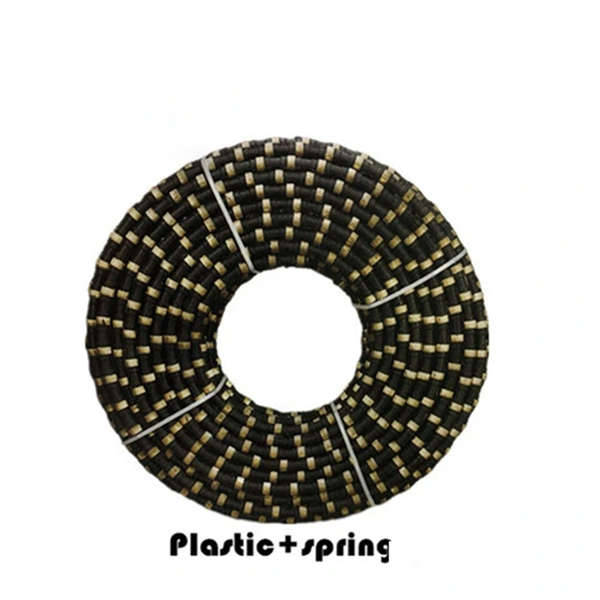

One of the key advantages of using a diamond cable wire saw is its remarkable efficiency. Unlike conventional saws that rely on blades, these saws use a thin, flexible wire embedded with diamond grains. This design allows for faster cuts through hard materials such as concrete, stone, and reinforced steel. The absence of a bulky blade also means reduced wear and tear, leading to lower maintenance costs over time.

Applications of Diamond Cable Wire Saws

The versatility of diamond cable wire saws makes them suitable for a wide range of applications. In demolition projects, they can cut through large structures with minimal vibration, reducing the risk of damage to surrounding areas. For mining operations, these saws enable precise extraction of valuable minerals from rock formations, increasing yield and reducing waste. Additionally, their ability to make clean, straight cuts is invaluable in the fabrication of countertops and other architectural elements.

Precision Cutting with Diamond Cable Wire Saws

When it comes to precision, few tools match the capabilities of a diamond cable wire saw. The thin wire ensures accurate cuts with minimal material loss, which is crucial in applications requiring high tolerances. Whether you’re slicing through thick slabs of granite or creating intricate designs in marble, the control offered by these saws is unmatched. This level of precision not only enhances the aesthetic appeal of finished products but also increases their structural integrity.

Maintenance and Durability of Diamond Cable Wire Saws

Despite their powerful performance, diamond cable wire saws are designed for ease of maintenance. Regular cleaning and occasional replacement of the diamond-impregnated wire are typically all that’s required to keep these machines running smoothly. Moreover, the robust construction of these saws contributes to their longevity, making them a cost-effective investment even in harsh industrial environments.

Advancements in Diamond Cable Wire Saw Technology

Continuous advancements in diamond cable wire saw technology are pushing the boundaries of what’s possible in cutting applications. Innovations such as variable speed controls and automated systems enhance user safety while improving operational efficiency. Research into more durable diamond compounds and stronger wires promises further improvements in cutting speed and tool life, ensuring that these saws remain at the forefront of industrial cutting solutions.

Choosing the Right Diamond Cable Wire Saw

Selecting the appropriate diamond cable wire saw depends on several factors including the type of material being cut, the required precision, and the frequency of use. Professionals should consider consulting with experienced suppliers who can provide guidance based on specific project needs. With the right choice, users can achieve optimal results, ensuring both efficiency and quality in every cut.

By leveraging the power and precision of diamond cable wire saws, industries can achieve higher standards of workmanship and productivity. As technology continues to evolve, these cutting tools will undoubtedly play an increasingly significant role in shaping the future of material processing across various sectors.

Request for Quotation

报错: 未找到这个表单