The Releated Products of Diamond Blade For Granite Cutting

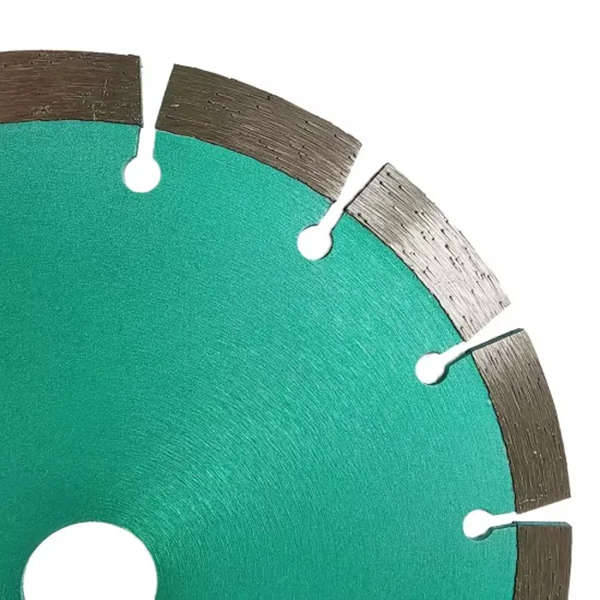

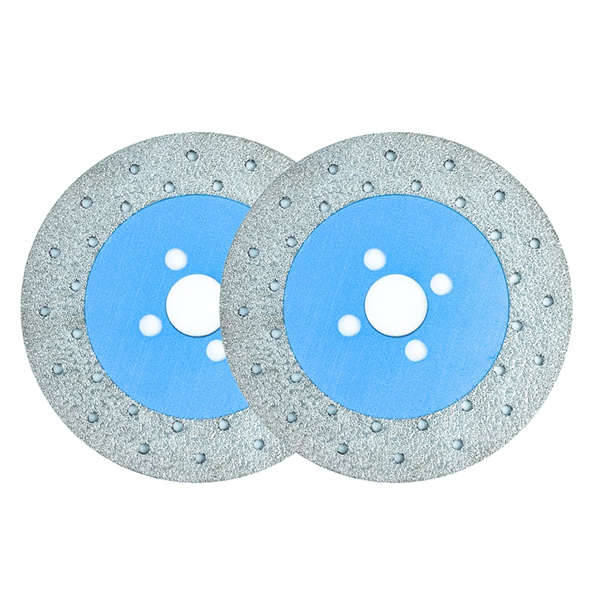

Diamond Blade For Granite Cutting

Table of Contents

Diamond Blade for Granite Cutting: Precision, Durability, and Efficiency

When it comes to cutting granite, a material renowned for its hardness and durability, having the right tool is crucial. A diamond blade for granite cutting stands out as one of the most effective solutions. This specialized tool not only ensures precision cuts but also extends the life of your equipment, reducing downtime and increasing productivity. In this article, we will explore the key features, benefits, and considerations when choosing a diamond blade for granite cutting.

Selecting the Right Diamond Blade for Granite Cutting

Selecting the appropriate diamond blade for granite cutting is critical to achieving clean, precise cuts. Factors such as the blade’s diameter, segment height, and bond type play significant roles in determining its performance. For instance, a higher segment height can provide better cutting depth, while a softer bond may be more suitable for harder materials like granite. Understanding these variables helps in making an informed decision that aligns with specific project requirements.

Benefits of Using a Diamond Blade for Granite Cutting

Using a diamond blade specifically designed for granite cutting offers several advantages over other types of blades. These benefits include:

– Increased Cutting Speed: Diamond blades can cut through granite much faster compared to abrasive wheels or other tools.

– Reduced Friction and Heat: The design of diamond blades minimizes friction and heat generation during the cutting process, leading to a cooler work environment and reduced risk of material damage.

– Longer Blade Life: Given the robust nature of diamonds, these blades tend to last longer, providing a cost-effective solution over time.

Maintenance Tips for Your Diamond Blade for Granite Cutting

Proper maintenance of your diamond blade for granite cutting is essential to ensure optimal performance and longevity. Regularly inspecting the blade for any signs of wear or damage, keeping it clean, and storing it in a dry place are fundamental practices. Additionally, following manufacturer guidelines on usage and care can significantly extend the blade’s life.

How to Choose the Best Diamond Blade for Granite Cutting

Choosing the best diamond blade for granite cutting involves considering several factors:

– Material Hardness: Granite varies in hardness; therefore, selecting a blade with the right bond hardness is crucial.

– Cutting Depth: Depending on the thickness of the granite, you might need a blade with a specific diameter and segment height.

– Application: Whether you are cutting slabs, countertops, or tiles, different applications may require different blade specifications.

Safety Precautions When Using a Diamond Blade for Granite Cutting

Safety should always come first when operating power tools, especially when using a diamond blade for granite cutting. Key safety precautions include wearing protective gear such as goggles, gloves, and dust masks. Ensuring the blade is properly secured and the machine is in good working condition before starting is also imperative. Always follow the manufacturer’s safety instructions to avoid accidents.

Troubleshooting Common Issues with Diamond Blades for Granite Cutting

Despite their durability, diamond blades can face issues like excessive wear, overheating, or poor cutting performance. Identifying and addressing these problems promptly can help maintain efficiency and prolong the blade’s life. Common solutions involve adjusting the water flow (for wet cutting), ensuring the blade is not overloaded, and periodically sharpening or replacing worn segments.

By understanding the nuances of diamond blades for granite cutting, you can make well-informed decisions that enhance your cutting capabilities, improve productivity, and ensure safer operations. Whether you’re a professional contractor or a DIY enthusiast, investing in quality tools is an investment in your success.

Request for Quotation

报错: 未找到这个表单