The Releated Products of Diamond Blade For Cutting Granite

Diamond Blade For Cutting Granite

Table of Contents

Diamond Blade for Cutting Granite: Precision, Durability, and Efficiency

In the world of construction and stonework, precision and durability are paramount. When it comes to cutting granite, one tool stands out as indispensable: the diamond blade. Designed specifically for materials like granite, these blades offer unparalleled performance, ensuring clean cuts and efficient work processes. This article delves into the intricacies of diamond blades for cutting granite, exploring their features, benefits, and proper usage.

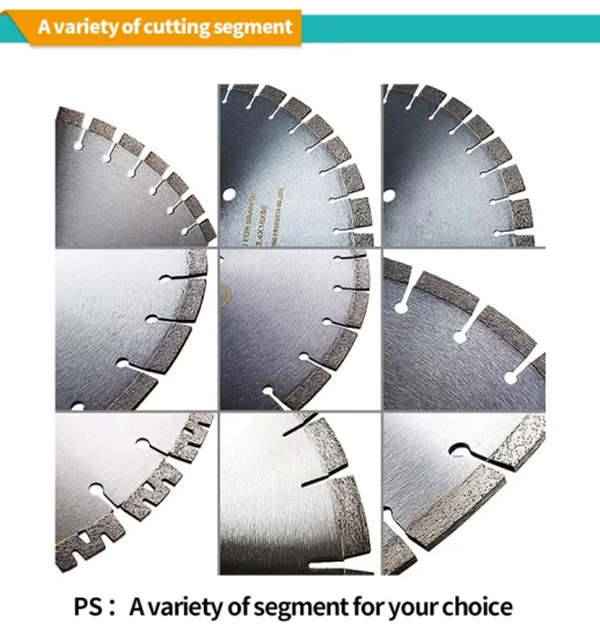

Diamond Blade for Cutting Granite: Key Features

A diamond blade for cutting granite is not just any ordinary tool. It’s engineered with a robust design that includes industrial-grade diamonds embedded in a metal matrix. These diamonds act as the cutting edge, while the matrix provides support and structure. The choice of metal for the matrix can vary, with options including bronze, steel, and even laser-welded constructions. Each type offers distinct advantages depending on the specific application and material being cut.

Choosing the Right Diamond Blade for Cutting Granite

Selecting the appropriate diamond blade for cutting granite is crucial for achieving optimal results. Factors such as the size of the blade, the bond hardness, and the segment height all play significant roles. Larger blades are better suited for deeper cuts, whereas smaller ones are ideal for precision work. Bond hardness refers to how tightly the diamonds are held within the matrix; softer bonds work well on harder materials like granite, as they allow the diamonds to wear down at a rate that matches the material being cut.

Maintenance and Care of Your Diamond Blade for Cutting Granite

To ensure longevity and maintain peak performance, proper maintenance of your diamond blade is essential. After each use, clean the blade thoroughly to remove any debris or residue. Store it in a dry place to prevent rusting and damage. Regular inspections for signs of wear and tear, such as cracks or chips, are also important. Addressing these issues promptly can prevent accidents and extend the life of your tool.

Techniques for Using a Diamond Blade for Cutting Granite

Using a diamond blade for cutting granite requires both skill and safety precautions. Always wear protective gear, including goggles, gloves, and a dust mask. Start by marking the cut line clearly on the granite surface. When operating the saw, apply steady pressure and let the blade do the work—avoid forcing it, as this can lead to overheating and decreased effectiveness. Cooling the blade during operation, typically through water spray, helps maintain its integrity and prolongs its lifespan.

Advantages of Using a Diamond Blade for Cutting Granite

The primary advantage of using a diamond blade for cutting granite is its ability to produce smooth, precise cuts with minimal effort. Unlike other types of blades, diamond blades can handle the extreme hardness and abrasiveness of granite without dulling quickly. They also generate less heat, reducing the risk of thermal damage to the stone. Additionally, diamond blades are versatile enough to be used for a variety of applications, from cutting countertops to shaping intricate designs.

Safety Considerations When Using a Diamond Blade for Cutting Granite

Safety must always come first when working with powerful tools like diamond blades. Familiarize yourself with the manufacturer’s instructions and guidelines. Keep the work area clear of bystanders and unnecessary objects. Use clamps or a vise to secure the granite piece being cut, preventing it from moving during the process. Lastly, never operate the blade without proper ventilation, as cutting granite can release harmful dust particles into the air.

By understanding the key features, proper selection, maintenance, techniques, and safety measures associated with diamond blades for cutting granite, professionals can achieve superior results while ensuring their own safety. Whether you’re a seasoned stonemason or just starting out, investing in high-quality diamond blades will undoubtedly elevate your craftsmanship and efficiency.

Request for Quotation

报错: 未找到这个表单