The Releated Products of Cutting Rocks With Water

Cutting Rocks With Water

Table of Contents

Cutting Rocks With Water: A Revolution in Material Processing

In the realm of industrial cutting techniques, water has emerged as a powerful tool for slicing through rocks and other hard materials. This method, known as waterjet cutting, harnesses the force of high-pressure water streams to achieve precise cuts without generating heat or altering the material’s surface properties. Let’s explore how this innovative technology works and its applications in various industries.

How Does Water Cut Rock?

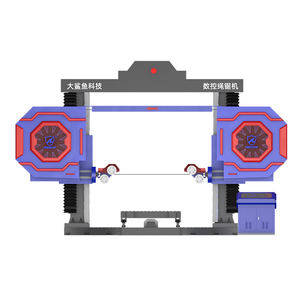

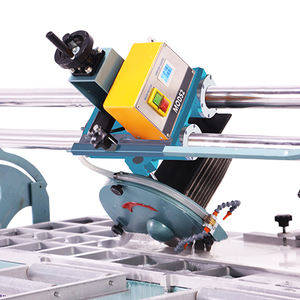

The principle behind waterjet cutting is relatively straightforward yet remarkably effective. By forcing water through a tiny nozzle at extremely high pressures—typically around 30,000 to 60,000 psi—the resulting stream becomes capable of cutting through almost any material, including rock. For harder substances, an abrasive such as garnet is often added to the water stream, significantly enhancing its cutting power. This combination allows for clean, precise cuts that can be made in virtually any direction, making it ideal for intricate designs and complex shapes.

Benefits of Using Water to Cut Rocks

Using water to cut rocks offers several advantages over traditional methods like sawing or drilling. First, because the process does not involve heat, there is no risk of thermal damage to the material being cut. This makes it particularly useful for materials sensitive to temperature changes. Additionally, waterjet cutting produces minimal dust and noise compared to mechanical cutting tools, creating a safer work environment. Furthermore, the ability to make highly accurate cuts without needing to change blades or bits reduces downtime and increases efficiency.

Applications of Waterjet Cutting in Rock Processing

Waterjet technology finds extensive use across multiple sectors where rock processing is essential. In the construction industry, it is used for cutting granite countertops, marble slabs, and other decorative stone pieces. The aerospace sector benefits from its precision when working with composite materials that contain embedded metals or fibers. Artists and sculptors also appreciate the versatility of waterjet cutting for creating detailed designs on various types of stone.

Maintenance and Safety Considerations When Cutting Rocks With Water

While waterjet cutting provides numerous benefits, proper maintenance and safety precautions are crucial for optimal performance and worker protection. Regular inspection and replacement of nozzles and seals ensure consistent cutting quality. Operators must wear appropriate personal protective equipment (PPE), including eye protection, hearing protection, and waterproof clothing, due to the high-pressure water spray. Employers should provide comprehensive training programs covering all aspects of safe operation and emergency procedures.

Future Innovations in Water-Based Rock Cutting

As technology continues to advance, so too does the potential for waterjet cutting. Researchers are exploring ways to increase efficiency by optimizing nozzle designs and developing new abrasives that could further enhance cutting speed and quality. Some are even investigating the use of alternative fluids or additives that might improve performance under specific conditions. These developments promise to open up new possibilities for industries reliant on rock cutting while reducing environmental impacts associated with traditional methods.

Conclusion

From ancient civilizations using simple tools to carve monumental structures out of solid rock, humanity has always sought better ways to manipulate this fundamental building block of our planet. Today, waterjet cutting represents one of the most advanced solutions available, offering unparalleled precision, flexibility, and sustainability. As we continue to innovate, it’s clear that the humble element of water will play an increasingly important role in shaping our future built environment.

Request for Quotation

报错: 未找到这个表单