The Releated Products of Cutting Granite Pavers

Cutting Granite Pavers

Table of Contents

Cutting Granite Pavers: Techniques and Tips for Precision

Selecting the Right Tools for Cutting Granite Pavers

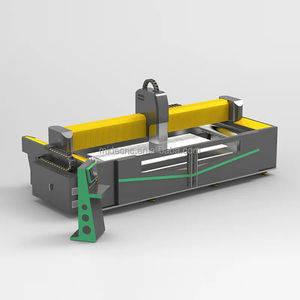

When it comes to cutting granite pavers, selecting the appropriate tools is crucial for achieving clean, precise cuts. Granite, being one of the hardest natural stones, requires specialized equipment to ensure accuracy and efficiency. A wet saw with a diamond blade is typically the go-to tool for this task. These saws not only provide the necessary power but also use water to cool the blade and reduce dust, making them ideal for working with granite.

Preparing Your Workspace for Cutting Granite Pavers

Before you start cutting granite pavers, it’s essential to prepare your workspace properly. This includes setting up a stable workbench or table where you can securely place the paver. Ensure that the area is well-ventilated to manage the dust produced during cutting. Additionally, having a steady supply of water nearby is important if you’re using a wet saw, as this will help keep the blade cool and minimize friction-generated heat.

Techniques for Accurate Cutting of Granite Pavers

Achieving accurate cuts when working with granite pavers requires both skill and patience. Begin by marking the cut lines on the surface of the paver with a pencil or chalk. Use a straight edge to ensure these lines are perfectly straight. When operating the saw, proceed slowly and steadily along the marked lines. Applying too much pressure can cause the blade to deviate from the intended path, leading to inaccurate cuts.

Safety Measures When Cutting Granite Pavers

Safety should always be a top priority when handling any kind of power tools, especially when cutting granite pavers. Always wear protective gear such as safety glasses, gloves, and a dust mask. The dust generated from cutting granite can be harmful if inhaled, so wearing a respirator is recommended. Keep your workspace organized and free of clutter to avoid accidents.

Troubleshooting Common Issues While Cutting Granite Pavers

Even experienced operators may encounter issues while cutting granite pavers. One common problem is chipping around the edges of the cut. This can often be mitigated by ensuring that the blade is sharp and by adjusting the speed at which you move the paver through the saw. If the cut seems jagged or uneven, check the alignment of the blade and make adjustments as necessary.

Maintaining Your Equipment for Cutting Granite Pavers

Proper maintenance of your cutting equipment is key to ensuring long-term performance and reliability. After each use, clean the saw thoroughly to remove any residue or debris. Check the condition of the diamond blade regularly; a worn or damaged blade can lead to poor quality cuts and increased risk of accidents. Lubricate moving parts according to the manufacturer’s instructions to keep the machine running smoothly.

By following these guidelines, you’ll be better equipped to handle the challenges associated with cutting granite pavers. Whether you’re working on a DIY project or a professional installation, taking the time to prepare adequately and use the right techniques can make all the difference in achieving high-quality results.

Request for Quotation

报错: 未找到这个表单