The Releated Products of Cutting Ceramic Tile Miter Saw

Cutting Ceramic Tile Miter Saw

Table of Contents

Cutting Ceramic Tile: Mastering the Miter Saw

When it comes to home improvement projects, cutting ceramic tile can be one of the most challenging tasks. Whether you’re a DIY enthusiast or a professional contractor, having the right tools makes all the difference. Among these essential tools, a miter saw designed for cutting ceramic tile stands out as a game-changer. This versatile piece of equipment not only simplifies the process but also ensures precision and efficiency.

Cutting Ceramic Tile Miter Saw: Precision Matters

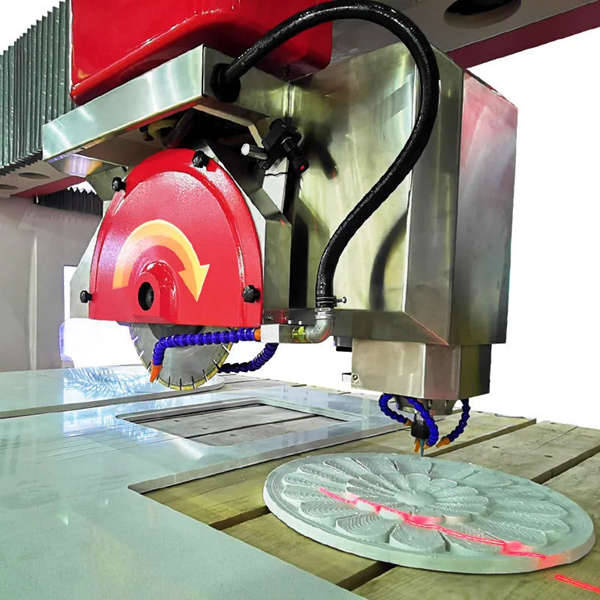

Precision is key when working with ceramic tiles. A cutting ceramic tile miter saw allows for accurate cuts, ensuring that your tiles fit perfectly every time. These specialized saws feature diamond blades that are specifically engineered to slice through hard materials like ceramic, providing clean edges without chipping or cracking. When choosing a cutting ceramic tile miter saw, consider models with adjustable angles and laser guides to enhance accuracy.

Benefits of Using a Cutting Ceramic Tile Miter Saw

Using a cutting ceramic tile miter saw offers several advantages over traditional methods. For starters, it significantly reduces the physical effort required, making large-scale projects more manageable. Additionally, the speed at which a cutting ceramic tile miter saw operates can drastically cut down on project completion times. Perhaps most importantly, the quality of cuts produced by these machines is superior, leading to a more professional-looking finish.

Maintenance Tips for Your Cutting Ceramic Tile Miter Saw

To keep your cutting ceramic tile miter saw performing at its best, regular maintenance is crucial. Start by cleaning the blade and guide rails after each use to remove any debris that could affect performance. Lubricating moving parts will help prevent wear and tear, extending the life of your tool. Lastly, store your cutting ceramic tile miter saw in a dry place to protect against rust and corrosion.

Selecting the Right Cutting Ceramic Tile Miter Saw

Choosing the right cutting ceramic tile miter saw depends on several factors, including the size of your project and the types of cuts you’ll be making. If you’re working on intricate designs that require complex angles, look for a model with a bevel capacity of at least 45 degrees. For larger tiles, ensure the saw has a wide enough base to support them during cutting. Consider also whether corded or cordless options better suit your needs based on portability and power requirements.

Safety Precautions When Using a Cutting Ceramic Tile Miter Saw

Safety should always come first when operating power tools. Before starting any project with your cutting ceramic tile miter saw, make sure to wear appropriate personal protective equipment (PPE), such as safety glasses, ear protection, and dust masks. Familiarize yourself with the manufacturer’s instructions and warnings, and never attempt to adjust settings while the machine is running. Keep fingers away from the blade area and use push sticks or blocks for guiding materials when possible.

Conclusion: Embrace the Power of a Cutting Ceramic Tile Miter Saw

In conclusion, investing in a high-quality cutting ceramic tile miter saw can transform how you approach tiling projects. From improving accuracy and speed to enhancing overall results, this powerful tool is an indispensable addition to any workshop. By following best practices for selection, maintenance, and safe operation, you’ll be well-equipped to tackle even the most demanding jobs with confidence. So why struggle with manual methods? Upgrade to a cutting ceramic tile miter saw today and elevate your craftsmanship to new heights!

Request for Quotation

报错: 未找到这个表单