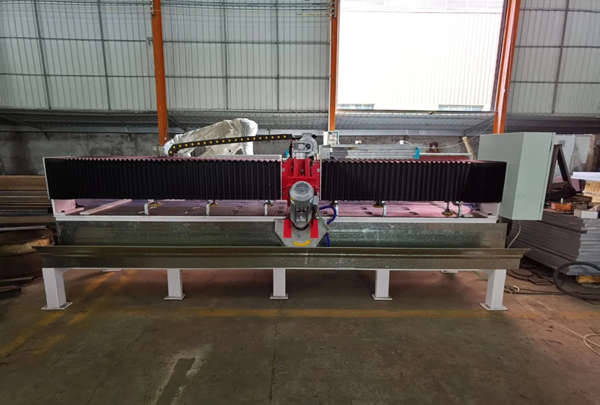

The Releated Products of Cut Ceramic Tile With Carbide Hole Saw

Cut Ceramic Tile With Carbide Hole Saw

Cut Ceramic Tile With Carbide Hole Saw: Precision and Power

Cutting ceramic tiles can be a challenging task for both DIY enthusiasts and professionals alike. However, with the right tools, such as a carbide hole saw, the job becomes much more manageable. This article will guide you through the process of cutting ceramic tiles using a carbide hole saw, ensuring clean cuts and minimal breakage.

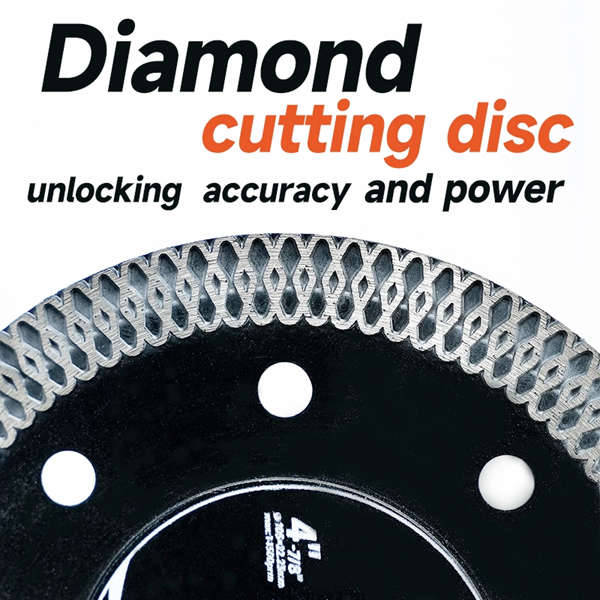

Choosing the Right Carbide Hole Saw for Ceramic Tiles

When it comes to selecting a carbide hole saw for cutting ceramic tiles, there are several factors to consider. First, ensure that the hole saw is made specifically for use on hard materials like ceramics. These saws typically have a high concentration of carbide particles embedded in their cutting edges, which allows them to cut through tough surfaces efficiently.

Another important consideration is the size of the hole saw. Measure the diameter of the holes you need to cut in your ceramic tiles accurately. Selecting a hole saw that matches these measurements will help you achieve precise results without damaging the surrounding tile.

Preparing Your Ceramic Tile for Cutting

Before you begin cutting your ceramic tile with a carbide hole saw, it’s essential to prepare the tile properly. Start by marking the exact location where you want to make the cut. Use a permanent marker or chalk to draw a clear and visible line. This step ensures that you maintain accuracy during the cutting process.

Next, secure the tile firmly onto a stable work surface. Using clamps or a vice can prevent the tile from moving while you’re cutting, reducing the risk of chipping or breaking. It’s also advisable to place a piece of scrap wood underneath the tile to protect your work surface.

Techniques for Cutting Ceramic Tiles With Carbide Hole Saws

Now that your ceramic tile is prepared, it’s time to start cutting. Begin by drilling a pilot hole at the center of the marked area using a carbide drill bit. This initial hole serves as a starting point for the carbide hole saw and helps guide it into position.

When using the carbide hole saw, apply steady pressure and allow the tool to do most of the work. Avoid forcing the saw, as this can lead to overheating and potential damage to the blade. Keep the saw lubricated with water or a specialized cutting fluid to maintain its efficiency and prolong its lifespan.

Maintaining Your Carbide Hole Saw for Ceramic Tiles

Proper maintenance of your carbide hole saw is crucial for long-term performance and durability. After each use, clean the saw thoroughly to remove any debris or dust that may have accumulated during cutting. Inspect the blade for any signs of wear or damage, and replace it if necessary.

Storing your carbide hole saw correctly is also important. Keep it in a dry place away from moisture and extreme temperatures. Consider investing in a protective case or cover to shield the saw from scratches and other forms of damage when not in use.

Troubleshooting Common Issues When Cutting Ceramic Tiles With Carbide Hole Saws

Despite careful preparation and proper technique, issues can still arise when cutting ceramic tiles with a carbide hole saw. If you encounter difficulty in making clean cuts or notice excessive vibration during operation, check that your saw is sharp and correctly aligned with the tile.

If the tile cracks around the cut area, try slowing down the cutting speed or applying less pressure. Adjusting these variables can often resolve the problem and result in cleaner, more precise cuts.

Conclusion

Cutting ceramic tiles with a carbide hole saw doesn’t have to be a daunting task. By choosing the right tool, preparing your tile properly, employing effective cutting techniques, maintaining your equipment, and troubleshooting any issues that arise, you can achieve professional-looking results every time. Remember, practice makes perfect, so don’t be discouraged if your first few attempts aren’t flawless. With experience, you’ll master the art of cutting ceramic tiles using a carbide hole saw.

Request for Quotation

报错: 未找到这个表单